Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Material: Widely used for product grading in mining, building materials, transportation, energy, chemical industry, etc.

Export Country: Middle East, South Asia, Southeast Asia, Eastern Europe and so on.

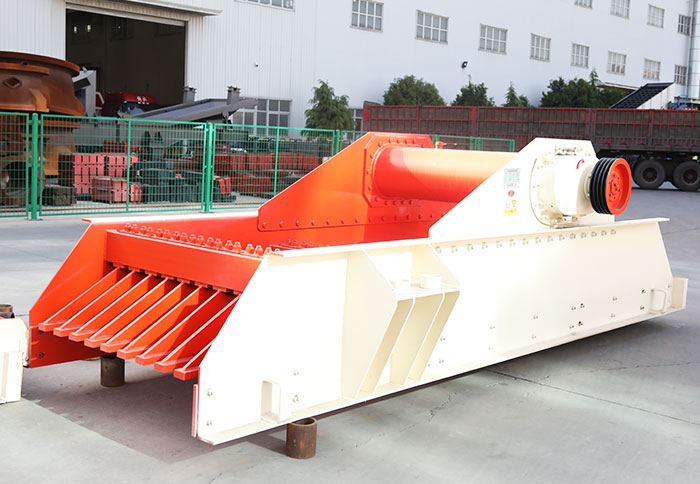

Vibrating feeder or vibrating grizzly feeder is mainly used to complete the feeding and batching for a variety of bulk materials in the ore dressing industry, metallurgy industry, coal, chemical industry, building materials and other industrial sectors.

In the production process, it can feed the massive and granular materials from the storage bin to the feeding device uniformly, timely and continuously. In the sand production line, its major role is to feed the crushing equipment and roughly screen the materials.

Vibratory feeder is conveying equipment for bulk materials, which cannot only convey the fine materials within 5mm particle size but also can transport large materials above 1m size. With its good adaptability, adjustable transmission capacity, uniform and continuous conveying functions, vibrating feeder is widely used in mining, building materials, chemical industry, metallurgy and other departments. For example, in the cement industry, vibrating feeders are often used for conveying bulk limestone and gypsum from the bottom of ore bin to the crusher evenly.

The vibrating feeder machine makes use of the eccentric block rotation in the vibrator to produce centrifugal force, so that the movable parts like screen box and vibrator can be forced to move continuously in a circular way or in approximately circular. The driving shaft is driven by the motor through the triangle belt, and then the passive shaft is rotated by the gear meshing on the active axle. The main and passive shafts rotate inversely at the same time, so that the slot body vibrates and the material flows continuously, so as to achieve the material conveying.

Vibrating feeder motor is sourced by vibration, which assures this feeding machine an excellent performance which can be seen as the following.

>>Pay timely checks on the vibrating feeder to see if it is vibrating stably. When swinging happens, power off the vibrating feeder and have a fix.

>>As the bearing parts lubrication is the key to normal operation, regular lubrication is needed every two months. And in high-temperature season, it is needed every month.

In Turkey, FTM vibrating feeder machine is used in a copper mine together with Jaw Crusher, Cone Crusher, and Round Vibrating Screen with a production capacity of 100TPH, input size of 750mm and output size of 12mm.

As one of the experienced vibratory feeder manufacturers, Fote Machinery has various types of vibrating feeder for sale. The vibrating feeder price in our company is reasonable in the mining machinery market. With advanced technology and good after-sale service, Fote Machinery is your best choice!

| Model | Max. Feeding Size (mm) |

Processing Capacity (t/h) |

Motor Power (kw) |

Obliquity of material trough (°) |

Trough size (mm) |

Dimensions (L×W×H)(mm) |

| GZD-650×2300 | 300 | 80-100 | 1.2×2 | 10-20 | 650×2300 | 2300×1360×780 |

| GZD-750×2500 | 350 | 100-130 | 1.5×2 | 10-20 | 750×2500 | 2500×1460×780 |

| GZD-850×3000 | 400 | 120-150 | 3×2 | 10-20 | 850×3000 | 3110×1800×1600 |

| GZD-1000×3600 | 500 | 150-200 | 3.7×2 | 10-20 | 1000×3600 | 3850×1950×1630 |

| GZD-1100×3600 | 580 | 240-300 | 3.7×2 | 10-20 | 1100×3600 | 3600×2050×1660 |

| GZD-1300×3600 | 650 | 450-600 | 7.5×2 | 10-20 | 1300×3600 | 3900×2350×1750 |

| GZD-1500×3600 | 1050 | 450-1000 | 7.5×2 | 10-20 | 1500×3600 | 3900×2000×1750 |

| GZD-2000×3600 | 1200 | 550-1000 | 10×2 | 10-20 | 2000×3600 | 3600×2000×1750 |

| GZD-2500×5000 | 1500 | 650-1500 | 18×2 | 10-20 | 2500×5000 | 5000×2500×1800 |

| ZSW-380×95 | 500 | 100-180 | 11 | 0-10 | 3800×960 | 3920×1640×1320 |

| ZSW-490×110 | 630 | 150-400 | 15 | 0-10 | 4900×1100 | 4980×1830×1320 |

| ZSW-490×130 | 750 | 400-700 | 22 | 0-10 | 4900×1300 | 4980×2580×2083 |

| ZSW-600×130 | 750 | 400-700 | 22 | 0-10 | 6000×1300 | 6082×2580×2083 |

| ZSW-600×150 | 800 | 500-900 | 30 | 0-10 | 6000×1300 | 6086×2662×1912 |

| ZSW-600×180 | 900 | 700-1300 | 45 | 0-10 | 6000×1500 | 6310×3262×2230 |

| ZSW-600×200 | 1200 | 800-1500 | 55 | 0-10 | 6000×2000 | 6310×3462×2230 |

| Model | Max. Feeding Size (mm) |

Processing Capacity (t/h) |

| GZD-650×2300 | 300 | 80-100 |

| GZD-750×2500 | 350 | 100-130 |

| GZD-850×3000 | 400 | 120-150 |

| GZD-1000×3600 | 500 | 150-200 |

| GZD-1100×3600 | 580 | 240-300 |

| GZD-1300×3600 | 650 | 450-600 |

| GZD-1500×3600 | 1050 | 450-1000 |

| GZD-2000×3600 | 1200 | 550-1000 |

| GZD-2500×5000 | 1500 | 650-1500 |

| ZSW-380×95 | 500 | 100-180 |

| ZSW-490×110 | 630 | 150-400 |

| ZSW-490×130 | 750 | 400-700 |

| ZSW-600×130 | 750 | 400-700 |

| ZSW-600×150 | 800 | 500-900 |

| ZSW-600×180 | 800 | 700-1300 |

| ZSW-600×200 | 1200 | 800-1500 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat