Trommel screener is a kind of sorting machine that is widely used in aggregates production and other industrial fields. It can control the garbage separating by particle size and has high sorting accuracy. Trommel screen cylinder body is generally divided into several sections depending on the specific situation of customized requirements. The sieve holes are arranged from small to large, and the size of the sieve hole on each section is the same.

The screen

There are mainly two factors of screen selection, the production process of the screen and the size of the screening hole.

The screen is usually typed as knitting and punching. The former type of screen is mainly made of round steel with the same wire diameter. If the proportion of the material is too large, it is easy to cause a deformation and material leakage on the trommel screen machine. Besides, producing a knitting screen is complex with higher cost and the maintenance cost is higher as well.

The punching screen is made of ordinary carbon steel or stainless steel. With the simple production process, the bent punching plate and joint of the interface are designed for more solid and durable service. Therefore, in the trommel screen market, the trommel screen equipped with a punch plate screen is the mainstream choice.

The size of the screen hole shall be qualified to meet different screening requirements. You can take a material test for judgment or offer material size information to professional engineers for consultation.

Converter

The converter of the trommel screen shall be able to work properly. In the screen cylinder's co-rotation, the converter should ensure a normal co-rotation. Inversion is forbidden in the co-rotation. Besides, deceleration should be carried out slowly to ensure that the screen body is still when reverse rotation happens. This is to avoid short circuit of the motor or serious deformation of the screen body.

The screening effect of the trommel screen

First-time buyers may pay more attention to the speed of the screen barrel. It is easy to ignore the screen barrel of material screening effect. Rotation is important, while the efficiency of the screen is another important factor.

When selecting a trommel screen, you can take the material to the factory for a test. In the test, it is clear to observe the screening efficiency, material discharging and whether blocking happens.

Other factors on the choice of trommel screen include the material and requirements of output, working environment and working period, etc. Investors can consult related engineers to reduce time-waste.

Trommel screen is aimed at grading various sticky and wet materials like refractory materials, coal, sand stone, coke, lime, gold sand, and so on. The finished product has uniform size to meet the production requirements.

It plays an important part in electric power, mining, coking plants, cement production, ore beneficiation, metallurgy, building materials and chemical industry and any other industrial areas.

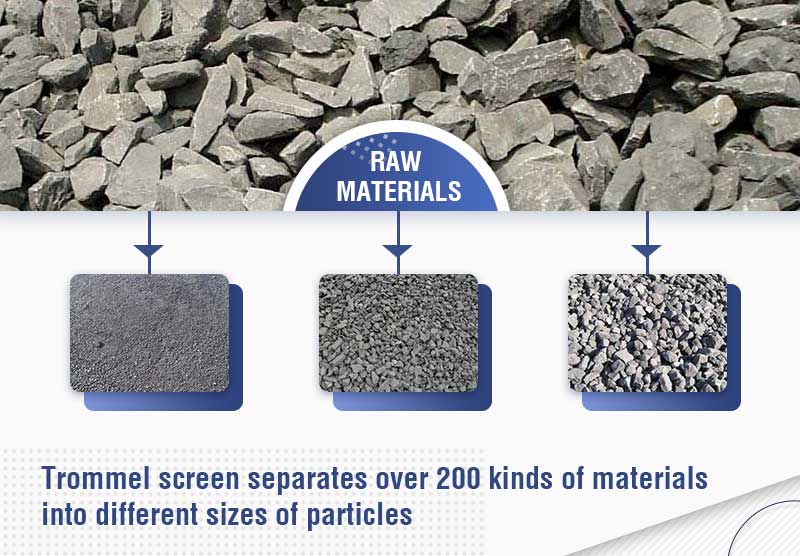

Trommel screen separate materials into different sizes of particles

Here are some specific examples of its applications.

1. In stone material factory, it is used to grade different sizes of stones and to separate the soil and stone powder.

2. In sand production line, trommel screen works itself to separating sand and stone.

3. In coal industry, operators usually use trommel screen in separating coal blocks and coal powder as well as in coal washing process.

4. In chemical industry and ore beneficiation line, trommel screen is used for different particles grading and to separate powder from blocks.

Applications of Trommel Screen

Fote Trommel Screen in Different Customer Sites

The trommel screen usually works with crushing machine and belt conveyor. The raw crushed materials are fed into the trommel screen.

Firstly, tilt the rotary trommel on the rack. The motor is connected with the drum device through the reducer and the shaft coupling to drive the drum device to rotate around its axis. When the material enters the drum device, due to tilt and rotation of the drum device, the material on the screen surface will be turned over and rolled.

Due to the effect of gravity, the qualified material (products under the screen) will be discharged through the port at the bottom of the back end of the drum, and the unqualified material (products on the screen) will be discharged through the discharge port at the end of the drum.

Thanks to the drum rotation and rolling, the material stuck in the sieve hole can be ejected to prevent the trommel screening machine from blocking.

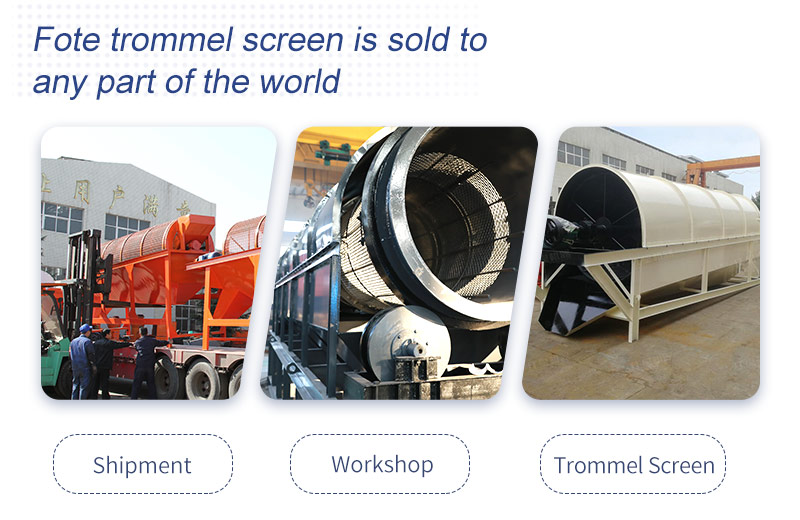

Fote Trommel Screen Shipment and in the Workshop

Although the trommel screen has simple structure, which needs low maintenance cost, due to a long service time, operators' unfamiliarity with the machine or other reasons, customers often encounter some problems in the operation. Based on customer feedback and their own experience, Fote engineers summarized some common failures and solutions to trommel screen.

| Faults | Causes | Solutions |

| Poor-quality finished product from trommel screen | Screen hole is blocked. | Clean the screen hole regularly |

| Low screen efficiency | The material is of high moisture. | Dewater the material ahead of time or increase the mesh of the screen hole. |

| Low rotating speed of the trommel screen | The conveyor belt is loose. | Adjust the equipment transmission belt tightness timely to avoid harm to the machine service life. |

| Hot bearing | The bearing needs to be oiled or cleaned. | Regularly clean and oil the bearing, replace the seal and check if the oil to the bearing meets the standards or not; replace the bearing if it is worn out seriously. |

| Locked trommel screen roller | The seal sleeve maybe blocked. | Clean the shaft sleeve |

| Irregular noise of the rotating trommel screen | Tightness degree of screen tightness, wearing degree of bearing, bolts to hold the parts, etc. | Pay regular check to screen, the bearings, bolts and other parts and timely adjust them according to standards. |

Last summer, Mr. Wong in Beijing consulted Fote engineer for trommel screen to separate aggregates from soil. He sent the project details to us including required capacity, feed size, and pics of the work environment.

With several emails and messages chat, Fote engineers offered the most suitable trommel screen solution. Though there are four sets of trommel screens, the one-time investment is reasonable due to the low cost of one set of trommel screen. And thanks to the simple structure of this trommel screen machine, the maintenance cost is rather low with a high separating efficiency.

I needed a trommel screen line with a capacity of about 200TPH, including 100TPH for 25-30mm particle, 30TPH for 5-10mm particle, and the rest for 15-20mm particle. The engineer paid carness and asked more details of the project including the budget and provided us with a cost-efficient solution.

So far, these four sets of trommel screen have worked very well for us with low failure rate.

Fote Trommel Screen in Beijing Customer Site

Fote Machinery has been committed to mineral processing technology research for more than 40 years, and its business units are specialized in the production of various types of trommel screen. The trommel screen design adopts mature production concept, and is equipped with professional technical research and development team, to create high quality trommel screen equipment for you!

As a professional trommel screen manufacturer, Fote Machinery provides you with a more authentic, more preferential equipment quotation, and it is your best choice to purchase affordable trommel screen. If you want to know the detailed quotation of equipment, free online consultation at quote@sinoftm.com

| Model | Yield(m³/h) | Power (kw) | |

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 12 | 100 | 5.5 |

| YTS1240 | 14 | 120 | 5.5 |

| YTS1250 | 15 | 140 | 5.5 |

| YTS1530 | 18 | 150 | 5.5 |

| YTS1540 | 18 | 150 | 7.5 |

| YTS1550 | 20 | 180 | 11 |

| YTS1560 | 22 | 200 | 11 |

| YTS2040 | 25 | 250 | 15 |

| YTS2050 | 30 | 300 | 15 |

| YTS2060 | 35 | 350 | 18.5 |

| Model | Yield(m³/h) | Power (kw) | |

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 12 | 100 | 5.5 |

| YTS1240 | 14 | 120 | 5.5 |

| YTS1250 | 15 | 140 | 5.5 |

| YTS1530 | 18 | 150 | 5.5 |

| YTS1540 | 18 | 150 | 7.5 |

| YTS1550 | 20 | 180 | 11 |

| YTS1560 | 22 | 200 | 11 |

| YTS2040 | 25 | 250 | 15 |

| YTS2050 | 30 | 300 | 15 |

| YTS2060 | 35 | 350 | 18.5 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat