Toothed roller crusher or teethed roller crusher is one kind of roller crusher playing a primary, secondary and tertiary role in crushing. It is actually simple in structure with relatively rotating rollers. There are sharp teeth on them, which are the main part of toothed roller crusher to break materials. These two rollers are made of special wear-resistant materials and set on a heavy and rigid bearing bed.

With advanced technology from German, etc., Fote toothed roller crusher can be commonly used in mine, mine, metallurgy industry, cement industry, power plant, and other industrial departments. Especially, toothed roll crusher performs outstandingly in crushing coal (containing coal gangue) in large-scaled coal preparation plant or coal mining plant.

Video of Fote Toothed Roll Crusher in Customer Site

For its two-roller structure, it is also called toothed roll crusher or double roll crusher. Fote toothed roll crusher can be divided into double roller crusher and four-roller series, customers can consult freely and get customized solutions according to their own needs.

Fote solutions on toothed roller crusher will take customer requirements as the leading reference. You can choose your own toothed roll crusher based on the discharged particle size needed.

The raw material market has been much tougher than before for the speeding-up city building and development. Because the resource is limited, more and more plants come to use material with soil or other refuses, some of which are not suitable to be crushed with traditional crushers like jaw crusher or impact crusher. While, here, toothed roller crusher will play its part.

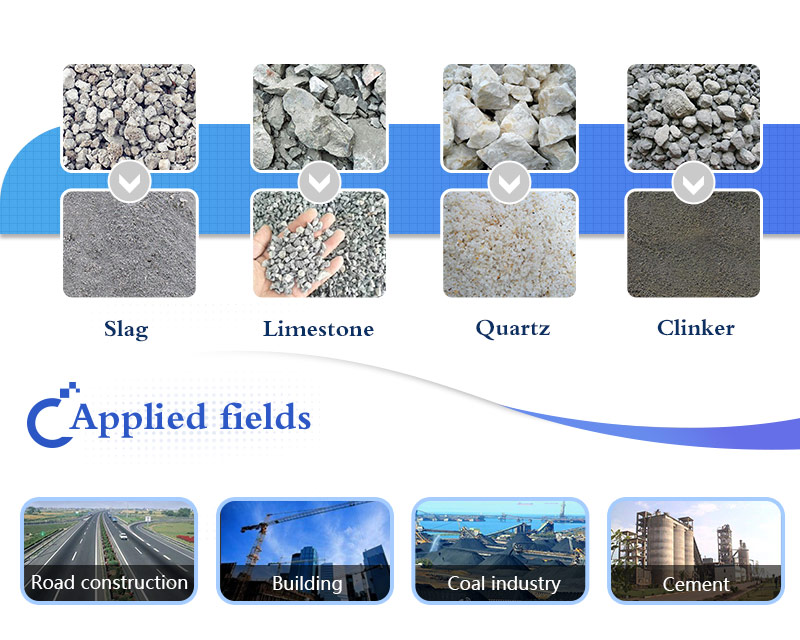

Examples of Toothed Roll Crusher Application

Due to the specially designed structure, toothed roll crushers have small bulk and high crushing ratio of 5-8, which can be employed to process hundreds of kinds of materials in diverse industrial departments.

√ In cement industry, it can be used to break concrete and limestone which are too large to be ground.

√ In mining department, toothed roll crusher is used to process raw ore for more convenient package, storage and transportation.

√ In brick and tile factories, workers use toothed roll crusher to break thick and wet material to apply them as filler.

√ In coal plants, toothed roller crushers are utilized to prepare coal especially, to crush raw coal that contains gangue.

√ In sand making plant, toothed roll crusher can be used as the primary crushing equipment to improve the crushing efficiency.

√ Other applications: pebble, quartz, anthracite, lignite, sinter, coke, slag, shale, and granite, etc. in metallurgy, chemical industry, and building materials industry

Applied fileds of toothed roller crusher

Toothed roll crusher mainly crushes materials by the mutual extrusion between two rollers, so the roller is its main component. The rollers, motor, wheels, and other parts are fixed on the foundation bed. When the toothed roller crusher works, the wheels get energy from the motor and drive the roller rotates. Materials fed between the rollers are squeezed to the required size and will be exhausted from the discharging opening beneath the bed. The finished product size is adjusted by the quantity or the thickness of the pads.

Toothed roll crusher is mainly composed of the roller, roller bearing, compaction and adjusting devices, driving device, etc.

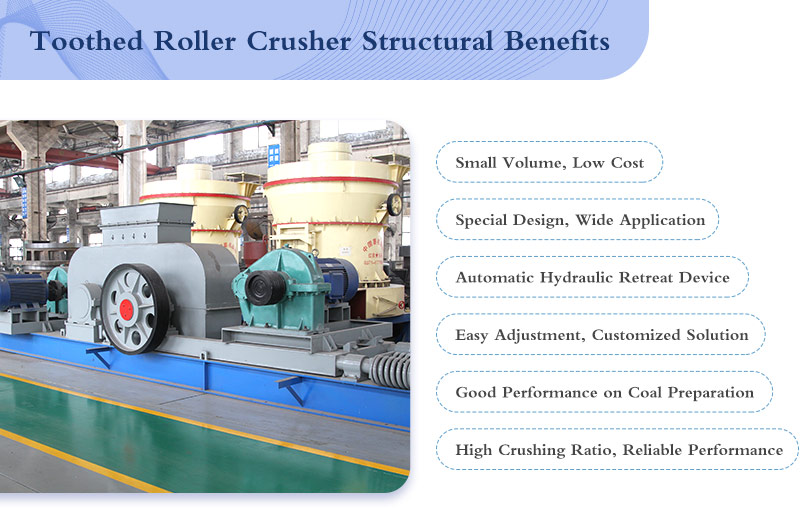

Structural Benefits of Toothed Roll Crusher

In 2017, Fote double toothed roll crushers were introduced to a Germany mining plant to be used in a pebble crushing line. This pebble production line has a capacity of 100TPH, input size of 50-200mm and output size below 50mm.

This foreman happened to know that toothed roller crusher can be used as the primary crushing equipment. He searched teethed roller crusher on Google and saw our web. After chatting with our sales, he got more details about toothed roller crusher including customized solution, the flow chart, the latest quotation and some maintenance tips, etc.

He paid a visit to Fote Machinery workshop one month after the chat. And he made a decision on the last day of his visit. So far, these toothed roller crushers have worked well for him with high crushing ratio.

Fote Toothed Roller Crusher Customer Site

The finished product size can be adjusted through virous methods, including the distance between the rollers, the teeth on the rollers, etc.

●The distance between the rollers

This is usually finished by gaskets between the rollers. The adjustment of the amount or thickness of gaskets affects the gap between the two rollers, which will change the discharged particle size.

●The teeth on the rollers:

The size of the number, size and sickness of the teeth on the rollers will also influence the discharged particle size.

Located in the machinery center, Zhengzhou, Henan, Fote Machinery (FTM) has witnessed most of Chinese mining machine development with about 40-year history. Based on tradition, Fote has introduced advanced international technology and formed its own product series.

Insisting the principle of environmental protection, Fote focuses itself on the research of low-noise and low-dust toothed roll crusher. Besides, over 360 Fote engineers is specialized in offering customized solutions based on customer need and providing consultation of prolonging your machine service life. Welcome to chat online or leave an online message to get the latest toothed roll crusher price.

Fote Toothed Roll Crusher Ready for Shipment

| Model | Roller diameter (mm) | Roller length (mm) | Max. Feeding Size (mm) | Discharging size(mm) | Output (t/h) | Motor power (kw) | Total weight(t) | Overall dimension (L×W×H) (mm) |

| 2PGC600×500 | 600 | 500 | 200-450 | 15-100 | 30-60 | 4P 11×2 | 3.8 | 2450×1800×950 |

| 2PGC600×800 | 600 | 750 | 300-600 | 20-120 | 60-100 | 4P 18.5×2 | 7.2 | 4500×1900×1350 |

| 2PGC800×1000 | 800 | 1000 | 500-800 | 30-150 | 100-160 | 4P 22×2 | 12.6 | 2550×2050×1100 |

| 2PGC1000×1000 | 1000 | 1000 | 700-950 | 30-200 | 150-200 | 6P 45×2 | 18.8 | 2780×4100×1550 |

| 2PGC1200×1200 | 1200 | 1200 | 800-1050 | 30-200 | 180-250 | 6P 55×2 | 29.5 | 2780×3200×1980 |

| 2PGC1500×1200 | 1500 | 1200 | 1000-1150 | 30-200 | 200-300 | 6P 75×2 | 38.6 | 8010×4500×2050 |

| Model | Max. Feeding Size (mm) | Discharging size(mm) | Output (t/h) |

| 2PGC600×500 | 200-450 | 15-100 | 30-60 |

| 2PGC600×800 | 300-600 | 20-120 | 60-100 |

| 2PGC800×1000 | 500-800 | 30-150 | 100-160 |

| 2PGC1000×1000 | 700-950 | 30-200 | 150-200 |

| 2PGC1200×1200 | 800-1050 | 30-200 | 180-250 |

| 2PGC1500×1200 | 1000-1150 | 30-200 | 200-300 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat