Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Material: Mineral ores, sand, ore powder, metal powder, gypsum powder, blast surface slag, limestone, quartz/silica sand, clay, coal slime, coal powder, sawdust, fly ash, river sand, gypsum, etc.

Three-drum dryer is also called three-cylinder dryer or triple-drum dryer. It is an improved type based on the single drum dryer and supported by the modern and advanced German technology. Three-cylinder dryer is mainly composed of three concentric circles with different diameters in inlaid combination. Compared with traditional drum dryer, the triple-drum dryer is with better seal technology and is equipped with more scientific machines. This dryer is commonly used for drying granular material with certain moisture and certain particle size range. For example, three-drum dryer can be used to dry clinker, sand, molding sand, slag, cinder, fine-grained clay, high temperature resistant and dusty particles.

Three-Drum Dryer

Three-drum dryer is widely used in building materials industry, metallurgy industry, ore dressing industry, chemical industry, cement and other industries. It is suitable for drying a variety of particles and powder in the above sectors. After drying, the humidity of the materials can reach 1% or below. Some application examples of three-drum dryer:

Three-Drum Dryer Application

Radiation, convection and heat conduction are mainly used in the drying process. And the dryer is set at a certain angle to utilize the gravity. When the hot wind in the oven gets the set temperature, the dryer works with the order from the PC system. Wet particle is then sent into the inner layer by the feeder evenly and goes with the scorching wind. The wet material is sent spirally by the fixed shoveling plate. Next, the material moves to another end of the oven and into the middle layer. This time, the wet powder inside moves forward against the blower machine stepping back in two steps. Here in the intermediate layer, heat from the inner layer and the middle layer is fully utilized, thus the drying efficiency is improved to the best situation. Lastly, dried material gets to the other end of the intermediate layer and moves into the outer layer in rectangular and multi-loop mode. Granular material that is dried to set moisture is blown out of the dryer. The rest will move more slowly because of its weight and be dried one more time in the outer layer to required humidity. Thus, the drying process is realized.

Working Principle of Three-Cylinder Dryer

Compared to traditional dryer, three-drum dryer has obvious advantages;

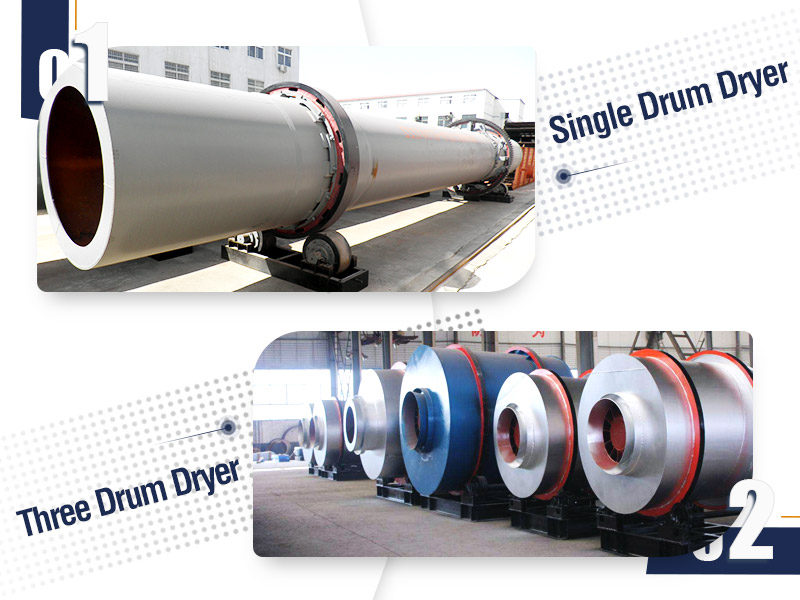

There are types of drum dryer like single drum dryer, double drum dryer, triple-drum one, and air-flow dryer, etc. It is always a confusion for customers to make a decision. Take single-drum dryer and three-drum drying machine for examples, let's make it clear how to choose a suitable dryer.

| Single Drum Dryer | Three Drum Dryer | |

| Diameter of Outer Cylinder(m) | 1.2-3.6 | 2.5-3.6 |

| Length(m) | 8.0-28.0 | 7.0-8.0 |

| Volume(m3) | 9.0-285.0 | 16.63-81.38 |

| Capacity(T/H) | 1.9-76.0 | Yellow Sand: 25-70 Slag: 20-65 |

From this table, it is clear that single-drum drying machine is of larger capacity and lower price. Besides, it is easier operated and maintained. As for the three-drum dryer machine, it takes less space but makes a better utilization of the heat. And it is of lower energy consumption than a single drum dryer when they take the same space. Therefore, if you need a less space-occupied but more efficient one, the triple-cylinder dryer is the best choice. Otherwise, if larger capacity and easier operation is needed, you would like to choose the other one.

Three-Drum Dryer VS Single-Drum Dryer

Fote three-drum dryer in Russia for drying sawdust with the capacity of 10TPH and the required output humidity of 5%.

Three-Cylinder Dryer at Customer Site

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand: 25-30 Slag: 20-25 |

Yellow sand: 30-35 Slag: 25-30 |

Yellow sand: 35-40 Slag: 30-35 |

Yellow sand: 45-50 Slag: 35-40 |

Yellow sand: 65-70 Slag: 60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

| Item/Unit/Model | Cylinder volume( m³ ) | Production capacity(T/h) |

| Φ2.5×7m | 16.63 | Yellow sand: 25-30 Slag: 20-25 |

| Φ2.7×7m | 16.63 | Yellow sand: 30-35 Slag: 25-30 |

| Φ3.0×7.0m | 52.678 | Yellow sand: 35-40 Slag: 30-35 |

| Φ3.2×7.0m | 52.678 | Yellow sand: 45-50 Slag: 35-40 |

| Φ3.6×8m | 81.38 | Yellow sand: 65-70 Slag: 60-65 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat