Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Pebble, gravel, granite, diabase, basalt, quartz, limestone, iron ore, sandstone, coal gangue, etc.

Symons cone crusher, also known as Symons crusher or compound crusher, is the integrated cone crusher with springs and hydraulic cylinder. It is suitable for crushing all kinds of medium and hard ores and rocks. Compared with the spring cone crusher, it has reliable structure, high production efficiency, convenient adjustment and economic usage. The spring safety system is the overload protection device, which protects the machine from the extraneous matter when it passes through the cavity. It adopts grease seal form to make the powder and oil isolated, so as to ensure the reliable work of the machine.

Symons Cone Crusher Workshop

Symons cone crusher has four kinds of crushing cavities to be selected, respectively coarse, medium, fine and ultra-fine crushing cavity. It is structured in standard Symons cone crusher and short-head Symons cone crusher. Generally, the standard Symons cone crusher has a larger feeding size and discharging size, therefore, it is more commonly used for coarse and medium crushing. While the short-head type of Symons cone crusher has a sharper cone with a smaller feeding size, which is better used for medium and fine crushing.

Symons cone crusher can be widely used in metal and nonmetal ore, cement factory, building industry and metallurgy industry, which is suitable for sand, iron ore, non-ferrous metal ore, granite, limestone, quartz rock, sandstone and pebbles. It is the preferred cone crusher in building, mine and coal industry.

Application of Symons Cone Crusher

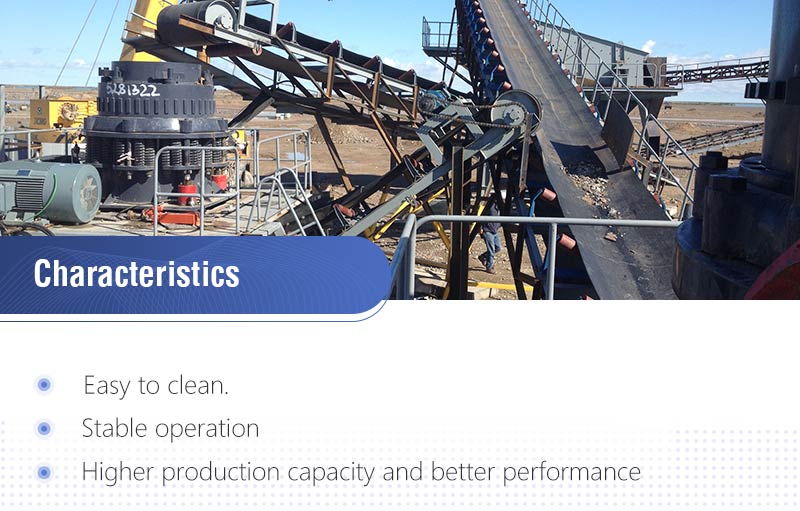

Advantages of Symons Cone Crusher

Symons cone crusher crushing cavity is composed of a fixed cone (or upper crushing wall) and movable cone (or lower crushing wall). The movable cone is set on the main axis, which is in the eccentric axis sleeve. When the Symons cone crusher works, the movable cone is rotating and swings with the main axis. The upper crushing wall and the lower crushing wall are moving towards and away from each other, which results in materials crushing and then being exhausted.

When foreign matter that cannot be crushed enters the crushing cavity, the springs around the Symons cone crusher body work. Bearing rings and adjusting rings will be raised and the springs are pressed. Thus, the outset is enlarged and the extraneous matter is exhausted.

Symons Cone Crusher Working Principle

In Serbia, FTM Symons cone crusher is used in Asphalt and Limestone Line equipped with jaw crusher, ball mill, rotary dryer, etc. with a production capacity of 100TPH, input size of 600mm and output size of 0.4mm

Symons Cone Crusher Customer Site

As the experienced Symons cone crusher supplier, Fote Machinery has won great support from customers internationally for our professionally centralized Symons cone crusher factory. We are here to offer free consultation including the Symons cone crusher price and Symons cone crusher instruction manual.

| Type | Model | Diameter of large end of crushing cone(mm) |

Adjusting Range of Discharge Opening(mm) |

Feed opening size of the open edge when recommending the min. Discharge opening (mm) |

Max.feeding size(mm) |

Processing capacity (t/h) |

Main motor power (kw) |

Machine weight (kg) |

| PSG 900 | 0910 | 914 (3′) | 9-22 | 102 | 85 | 45-91 | 6P 75 | 9980 |

| 0917 | 13-38 | 175 | 150 | 59-163 | ||||

| 0904 | 3-13 | 41 | 35 | 27-90 | ||||

| 0906 | 3-16 | 76 | 65 | 27-100 | ||||

| PSG 1300 | 1313 | 1295 (4¼′) | 13-31 | 137 | 115 | 109-181 | 6P 160 | 22460 |

| 1321 | 16-38 | 210 | 178 | 132-253 | ||||

| 1324 | 19-51 | 241 | 205 | 172-349 | ||||

| 1306 | 3-16 | 64 | 54 | 36-163 | ||||

| 1308 | 6-16 | 89 | 76 | 82-163 | ||||

| 1310 | 8-25 | 105 | 89 | 109-227 | ||||

| PSG 1600 | 1620 | 1676 (5½′) | 16-38 | 209 | 178 | 181-327 | 6P 250 | 43270 |

| 1624 | 22-51 | 241 | 205 | 258-417 | ||||

| 1626 | 25-64 | 269 | 228 | 299-635 | ||||

| 1607 | 5-13 | 70 | 60 | 90-209 | ||||

| 1608 | 6-19 | 89 | 76 | 136-281 | ||||

| 1613 | 10-25 | 133 | 113 | 190-336 |

| Type | Model | Max.feeding size(mm) |

Processing capacity (t/h) |

| PSG 900 | 0910 | 85 | 45-91 |

| 0917 | 150 | 59-163 | |

| 0904 | 35 | 27-90 | |

| 0906 | 65 | 27-100 | |

| PSG 1300 | 1313 | 115 | 109-181 |

| 1321 | 178 | 132-253 | |

| 1324 | 205 | 172-349 | |

| 1306 | 54 | 36-163 | |

| 1308 | 76 | 82-163 | |

| 1310 | 89 | 109-227 | |

| PSG 1600 | 1620 | 178 | 181-327 |

| 1624 | 205 | 258-417 | |

| 1626 | 228 | 299-635 | |

| 1607 | 60 | 90-209 | |

| 1608 | 76 | 136-281 | |

| 1613 | 113 | 190-336 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat