Email (quote@sinoftm.com), we will reply to you within 24 hours

Packing: Bags

Application: Cement, ball mill, coal mill, slag mill in mining, power plant, silicate products, new building materials, refractory materials, chemical fertilizer, ferrous and nonferrous metal processing, glass ceramics and other production industries.

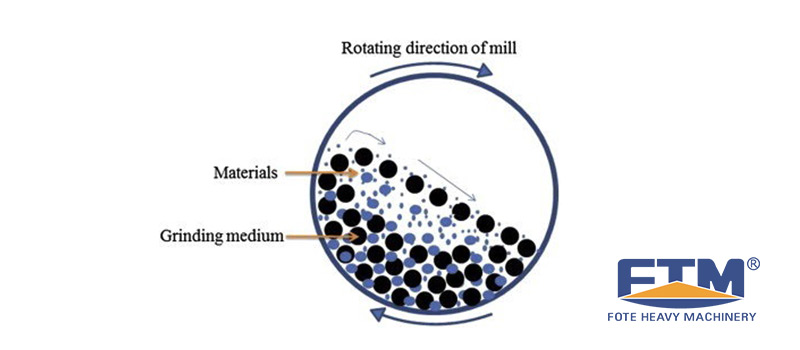

Steel ball is an important basic part of ball mill, and its main function is to grind, which makes the material more fine. It can be widely used in cement, building materials, metal ore, coal power, chemical, ceramics and other industries powder preparation and deep processing. The products with high hardness, small wear, good toughness, and less damage characteristics. In the production process, the hardness of wear-resisting steel ball will be further improved, and the wear resistance will also be improved. At the same time, it can improve the production capacity of ball mill and increase the recovery rate of concentrate. The steel ball of ball mill also can be called grinding steel ball and grinding ball.

The finished product has high hardness, low wear, good toughness and less broken. The hardness of wear-resistant steel balls will be further enhanced and the abrasion resistance will be increased during the production process. At the same time, it can improve the production capacity of ball mill and increase the specific surface area of cement as well as the concentrate recovery rate. The steel ball of ball mill also can be called grinding steel ball and grinding ball.

According to different materials, Fote Machinery steel balls can be divided into chrome steel ball, high manganese steel ball, and alloy steel ball. According to different processing technology, it can be divided into forged steel ball and casting steel ball.

Steel ball with different specifications and materials has different prices. We can help you choose and recommend the most suitable types of steel balls with the lowest cost according to your requirements. In addition, Fote Machinery also produces wear-resistant cylpebs with a variety of models and different materials. We can produce specific wear-resistant cylpebs according to the requests of customers. Customers are welcomed to make inquiries!

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat