Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, copper, zinc, lead, gold, etc.

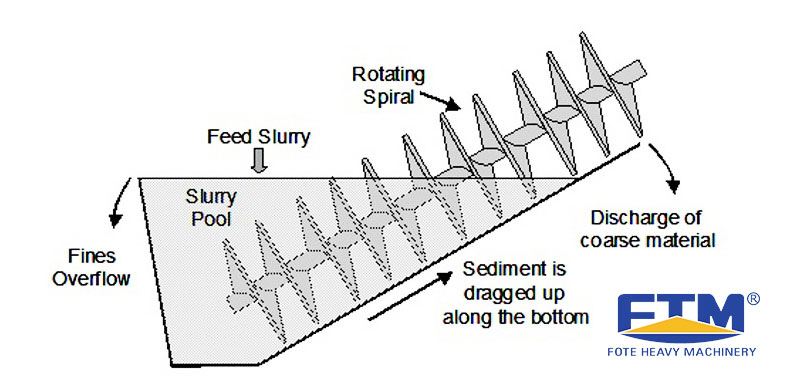

Referred to as the classifier or horizontal spiral classifier, the spiral classifier is one kind of equipment for the ore processing plant. It is the device for mechanical classification based on the principle that the specific gravity of a solid particle is different, therefore the rate at which it precipitates in a liquid also is different. Spiral classifier is used to treat alluvial placer, especially for those with high dissociation degree and flat shape of mineral monomer. Spiral classifier and ball mill generally cooperate, mostly used for mineral processing. The classifier has the characteristics of simple structure, reliable operation, convenient operation, high efficiency and energy saving.

The spiral classifier works by virtue of the principle that the size and specific gravity of solid particles are different, so the sedimentation rate in liquid is different. Fine ore particles float in the water and overflow, while coarse ore particles sink at the bottom of the tank and are discharged by spiraling upward to perform mechanical classification. It can filter out the material, and then use spiral sheet to screw the coarse material into the feed port of the mill, and discharge the fine material from the overflow pipe.

The base is made of channel steel and the body is welded with steel plate. The screw shaft has a water inlet head, a shaft head and a pig iron sleeve, which are wear-resistant and durable. Lifting device is divided into electric and manual. Spiral Classifier structure: grader is mainly composed of transmission device, screw, groove, lifting mechanism, lower support (bearing bush) and discharge valve.

In order to ensure efficient and continuous operation of the equipment, not only the equipment maintenance is required in the later stage of the operation, but also the inspection work in the early stage is indispensable. Fote Spiral classifier manufacturer list a few points for users for reference:

The horizontal spiral classifier produced by Fote Machinery is guaranteed in quality, and has many specifications and models, which can better meet the production needs of large, medium and small enterprises. The Fote spiral classifier also has affordable price. In the operation, the investment cost of the enterprise can be better reduced, and the income can be increased, so that the customer can recover the cost more quickly.

Fote Machinery is a professional spiral classifier manufacturer in China, which has reasonable price, considerate service and complete models, such as sand classfier as well as spiral classifier for gold, copper, zinc, lead, etc. If you want to know about our latest quotation, please chat with us online, leave us a message below or write emails to us. Thank you!

| Model | Spiral Diameter (mm) |

Trough Length (mm) |

Spiral rotate speed (r/min) |

Processing capacity(t/d) |

Motor Power (kw) |

Dimensions (mm≤) |

Total weight (t) |

||||

| Sand -return |

Overflow | For driving |

For lifting |

Length | Width | Height | |||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | ---- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11.0 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41.0 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73.0 |

| 2FC-30 | 14300 | 23300 | 1410 | ---- | ---- | 17091 | ---- | 8680 | 84.8 | ||

| Model | Spiral Diameter (mm) |

Spiral rotate speed (r/min) |

| FG-3 | 300 | 12-30 |

| FG-5 | 500 | 8-12.5 |

| FG-7 | 750 | 6-10 |

| FG-10 | 1000 | 5-8 |

| FC-10 | ||

| FG-12 | 1200 | 4-6 |

| FC-12 | ||

| 2FG-12 | ||

| 2FC-12 | ||

| FG-15 | 1500 | 4-6 |

| FC-15 | ||

| 2FG-15 | ||

| 2FC-15 | ||

| FG-20 | 2000 | 3.6-5.5 |

| FC-20 | ||

| 2FG-20 | ||

| 2FC-20 | ||

| FG-24 | 2400 | 3.67 |

| FC-24 | ||

| 2FG-24 | ||

| 2FC-24 | ||

| 2FG-30 | 3000 | 3.2 |

| 2FC-30 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat