Sludge drying is a process to dewater and recycle high-moisture sludge as resource. there are mainly two ways to dry sludge, natural drying and mechanical drying. The latter is more efficient. The removal of water reduces the sludge quality and volume, which is to make it convenient to be store and transport the sludge. With mature and advanced international technology from Europe, etc., Fote solution on sludge drying process is based on the properties, like high water content, high organics content, and low specific gravity, etc.

Video of sludge dryer work site

According to different customers' needs, Fote offers sludge drying machine with different heat sources.

✔ Solid fuel like coal

✔ Gaseous fuel like gas, steam, etc.

✔ Liquid fuel like oil, etc.

Sludge Dryer

Produced from sewage disposal, sludge actually can be transformed by special designed sludge dryer equipment into a kind of green fuel and resource. Sludge is an extremely complex heterogeneous material composed of organic fragments, bacteria, inorganic particles, colloids, etc. Sludge has the characteristics of high moisture, high organic matter content, fine particle and small specific gravity.

Sludge dryer plays a key role in dehydrating and drying wet sludge to a certain moisture. Dried sludge can be used in agriculture to improve the soil, in building materials production to be the raw material of cement and in brick making. Besides, sludge dryer can be used to make biochemical fiberboard.

Applications of Sludge Dryer

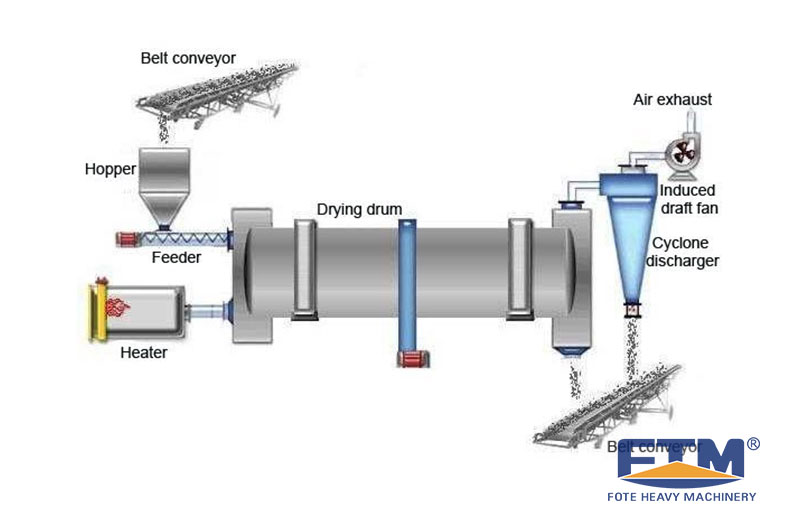

It is mainly composed of barrel, supporting device, driving device and sealing device, etc. The working areas include discharging area, lifting board area, cleaning area and feeding area.

Stucture of Sludge Dryer

An efficient use of sludge brings environmental protection as well as over-expected economic benefits.

Ⅰ. Reducing Weight and Volume

Sludge dryer reduces the sludge volume and weight by evaporation of water in it, making it easier to store and transport.

Ⅱ. Stabilize Sludge

Drying can stabilize the sludge, thus reducing the putrid smell and improving the disinfection effect.

Ⅲ. Simplify the Next Process

Either in following sludge disposal or in direct recycle process, sludge drying equipment plays an essential part of boosting the calorific value of sludge, which makes sludge easier to be used as fuel.

There are two commonly used types of sludge dryer machine, single-cylinder rotary sludge dryer and high-viscosity sludge drying equipment.

The first is newly developed from ordinary rotary dryer with cleaning device, breaking device and others inside. For drying material with a certain viscosity and smaller particle size, single-cylinder rotary sludge dryer is the better choice.

The latter usually uses hot-air spiral-blade drying technology with double or three shafts alternative according to the viscosity of the sludge. This drying machine can dry sludge with humidity below 85% to 12% or below just one time. And this drying process takes less time like 2-10 mins.

Fote Worker at Rotary Dryer Workshop

As mentioned, the main source of sludge is sewage disposal. In the city building, sewage disposal is always a hard nut to crack for local authorities. It is mainly for the reason that at present the urbanization is increasing at a surprising speed and the city improvement is one of the leading tasks.

In early 2019, an owner who runs a sewage plant in Singapore found the page of Fote sludge dryer. By chatting online with Fote sales, he came to know some details of sludge dryer selection. In the following communication, he was impressed by the profession and patience. Half and a month later, he introduced a medium sludge dryer machine from Fote Machinery (FTM).

With the site installation guidance and operation training, this sludge drying equipment has worked well for now. Here are the details of the drying line.

● Dried Material: Sludge

● Feed Moisture: About 75%

● Discharge Moisture: 2%

● Capacity: 15TPH

Fote Sludge Dryer at Customer Site

Situated in the Machinery Central, Zhengzhou Province, Henan Fote Heavy Machinery Co., Ltd. is one of the most professional sludge dryer manufacturers in China, and there are many types of sludge dryer for sale. Professional Fote engineers offer free consultation based on your requirements including sludge dryer price, solutions, flow chart, etc. Besides, two-week delivery, site installation guidance and operation training are available.

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (℃) | Main Motor (kw) | Weight (t) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell Length (m) | Shell cubage (m³) | Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 |

Φ1.2×10 | 11.3 | 2.4~3.0 |

Φ1.5×12 | 21.2 | 4.5~5.7 |

Φ1.5×14 | 24.7 | 5.3~6.6 |

Φ1.5×15 | 26.5 | 5.7~7.1 |

Φ1.8×12 | 30.5 | 6.5~8.1 |

Φ1.8×14 | 35.6 | 7.6~9.5 |

Φ2.2×12 | 45.6 | 9.7~12.2 |

Φ2.2×14 | 53.2 | 11.4~14.2 |

Φ2.2×16 | 60.8 | 13.0~16.2 |

Φ2.4×14 | 63.3 | 13.5~16.9 |

Φ2.4×18 | 81.4 | 17.4~21.7 |

Φ2.4×20 | 90.4 | 19.3~24.1 |

Φ2.4×22 | 99.5 | 21.2~26.5 |

Φ2.6×24 | 127.4 | 27.2~34.0 |

Φ3.0×20 | 141.3 | 30.1~37.7 |

Φ3.0×25 | 176.6 | 37.7~47.1 |

Φ3.2×25 | 201 | 42.9~53.6 |

Φ3.6×28 | 285 | 60.8~76.0 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat