Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: sawdust, wood chips, wood shavings, clay, limestone, ardealite, dry-mixed mortar, grain slag, coal slime, ore powder, etc. in construction materials, metallurgy, chemical and other industries.

Sawdust dryer is one type of rotary dryer that is specially designed for drying sawdust, wood chips, straw and charcoal, etc. It has high drying intensity, short drying time, large production capacity, high efficiency, small occupied area, easy operation and maintenance, etc. It is also known as sawdust drying machine or sawdust rotary dryer. Mainly, there are two types of sawdust dryer machine named as airflow sawdust dryer and three-channel dryer. The latter is generally used in the sawdust drying process.

Sawdust Dryer Ready For Shipment

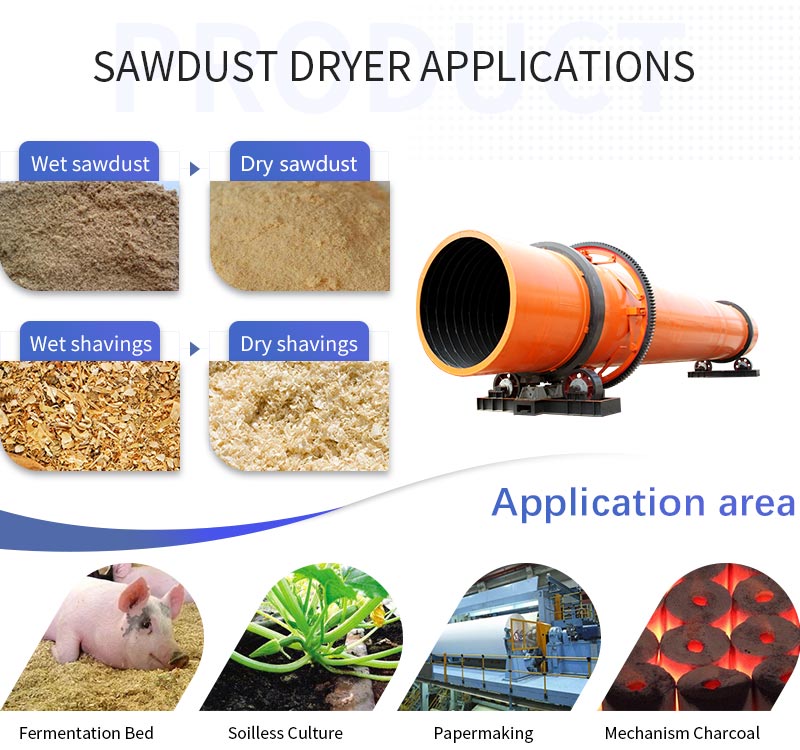

Sawdust refers to as the dust, chips, shavings and other materials left when wood is processed. Dried sawdust is widely used as fuel, filler, etc. As a result, sawdust dryer machine is also applied to many fields as follows:

Fuel processing: dried sawdust when briquetted is the key raw material in the fuel industry, like in heating supply system, power plant and so on;

Furniture industry: sawdust rotary dryer is used to dry the wet sawdust to a certain humidity, which is for the shaving board making, plywood making, etc.

Paper Making Industry: dried sawdust can be the raw material when make paper, therefore, this sawdust drying machine plays an initial part;

Edible fungus cultivation: the sawdust which is dried to the required moisture can be to cultivate mushrooms, fungus mushrooms, needle mushroom and agaric mushroom.

Examples of Sawdust Dryer Application

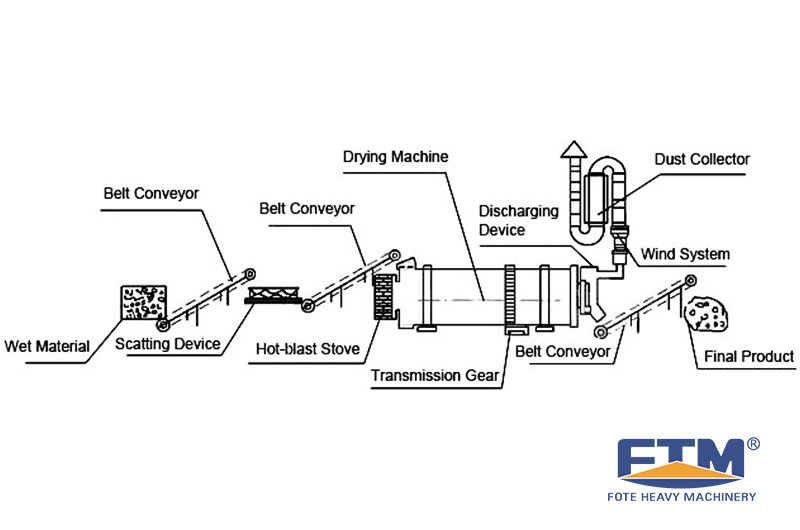

Sawdust Dryer is mainly composed of a heating furnace, inlet, rotating cylinder, filtering cylinder, conveying pipe, cooling tube and the outlet.

1. The sawdust is fully dried in the rotating cylinder;

2. Sawdust is fully dispersed again before entering into the material conveying pipe, so that the evaporation will be faster;

3. The material is boiling in the tube, the hot air and material will fully contact with each other to complete the drying process.

Sawdust Dryer Structure and Process

Faced with numerous changes and threats, Fote keeps on the research of how to increase the efficiency of the sawdust dryer and finds some tips.

1>> Replace the spiral conveying blades at the feeding end with 6mm steel triangular stiffened plates. It is to lower the sawdust speed in the high-temperature zone and to make a maximum utilization of the heat.

2>> Build central X-shaped lifting blades to prolong the residence time of the material and improve the heat transformation;

3>> Change the angle of the feeding tube. With the standard of not to influence the feeding efficiency, lift the blanking cylinder as much as possible. The top of the lifted tube shall not touch the material retaining ring. The part of the tube inside the cylinder shall be not too long and the material falls within the 200mm of the retaining ring. Thus, a material screen is formed and heat transformation is enhanced.

This Fote sawdust dryer is used in Pakistan with a capacity of about 10TPH. The customer saw the post from our sales on WhatsApp of rotary dryer. He clicked the link to our web and left an online message. After contact with him and got the confirmed reply, Fote engineer offered him three solutions with capacity from 5.7-15TPH. Finally, he chose the sawdust dryer of ModelΦ2.2x12. Here sawdust is dried from 15% to about 2%, which is directly used for smoked fuel, compression plate production and in other industries. This rotary dryer machine has worked well for him for about half and two years according to the feedback from him. Besides, Fote engineers assure him a reliable after-service.

Fote Sawdust Dryer Customer Site

Fote Machinery, founded in 1982, is one of the oldest machinery manufacturing plants in Henan Province and established the joint-stock co., Ltd in 1995 to be specialized in producing the large-scale mineral machine. Green industry and internationalization route have always been one of Fote's strategic ideas. So far, Fote has introduced a number of advanced technologies from Germany, Japan, the United States and other countries. Therefore, Fote sawdust drying technology is trustworthy. You can chat online with professionals or leave messages online for customized solutions, flow charts, sawdust dryer quotations, etc. Fote has a variety of models of sawdust dryer for sale, which can meet the requirements of large, small and medium-sized enterprises.

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (℃) | Main Motor (kw) | Weight (t) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell Length (m) | Shell cubage (m³) | Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 |

Φ1.2×10 | 11.3 | 2.4~3.0 |

Φ1.5×12 | 21.2 | 4.5~5.7 |

Φ1.5×14 | 24.7 | 5.3~6.6 |

Φ1.5×15 | 26.5 | 5.7~7.1 |

Φ1.8×12 | 30.5 | 6.5~8.1 |

Φ1.8×14 | 35.6 | 7.6~9.5 |

Φ2.2×12 | 45.6 | 9.7~12.2 |

Φ2.2×14 | 53.2 | 11.4~14.2 |

Φ2.2×16 | 60.8 | 13.0~16.2 |

Φ2.4×14 | 63.3 | 13.5~16.9 |

Φ2.4×18 | 81.4 | 17.4~21.7 |

Φ2.4×20 | 90.4 | 19.3~24.1 |

Φ2.4×22 | 99.5 | 21.2~26.5 |

Φ2.6×24 | 127.4 | 27.2~34.0 |

Φ3.0×20 | 141.3 | 30.1~37.7 |

Φ3.0×25 | 176.6 | 37.7~47.1 |

Φ3.2×25 | 201 | 42.9~53.6 |

Φ3.6×28 | 285 | 60.8~76.0 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items | Inside diameter of outer shell (mm) | Inside diameter of inner shell (mm) | Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat