Sand making machine is also called sand maker. It is a kind of fine crusher specially used for aggregate production of artificial sand, which is the tertiary or quaternary crusher.

Fote sand making machine is developed by Fote engineers combined with their own rich experience with German mature technology.

Fote Sand Making Machine in Fote Factory

Usually, together with the primary and secondary crushing equipment, the sand making machine produces 0-5mm particles.

With the special and ingenious angle of crushing, the grouped crushing methods of stone to iron and stone to stone realize the cubic shape of finished product with uniform particle size.

| Maximum feed size of 3 types of sand maker (mm) | |||

| HVI sand maker | VSI sand maker | Vertical shaft impact sand maker | |

| Sand making | <30-<50 | - | - |

| Sand shaping | <35-<55 | - | - |

| Soft materials | - | 35-50 | - |

| Hard materials | - | 30-45 | - |

| - | - | 35-60 | |

Flaky sand particles may produce coarse concrete, resulting in spongy concrete. While the cubic artificial sand can reduce the porosity by 5%-6%, which can not only increase the packing area and save storage space but also increase the strength of concrete and other building materials.

Early construction sand came from natural sand in rivers. However, with the development of infrastructure, excessive exploitation of natural sand caused a restriction.

The demand for construction sand is still growing. The artificial sand produced by sand making equipment becomes a substitute for natural sand for its high adhesion and high compressive resistance.

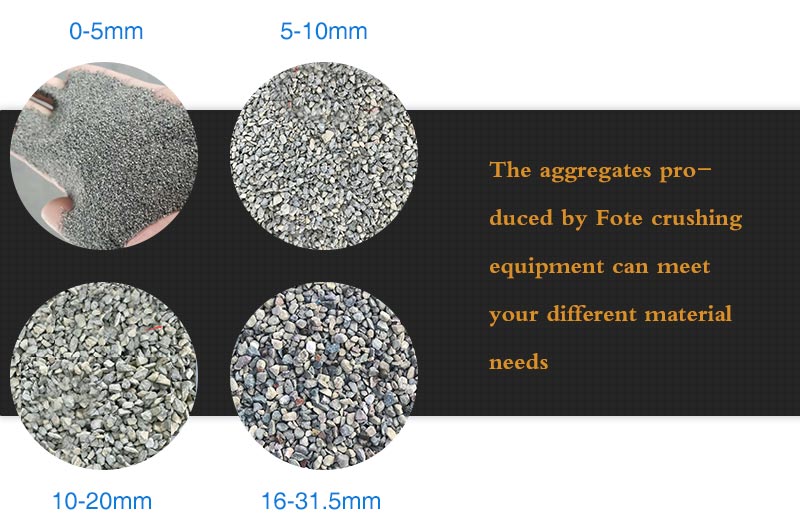

Different size of aggregates

Fote Machinery has three sand making machines for sale, HVI sand making machine, VSI sand making machine and vertical shaft impact sand making machine.

Because of the high efficiency, large capacity and reliable operation, the sand machine is extensively used in various industrial fields in the era of energy-saving and environment-care.

Three models of Fote Sand Making Machine

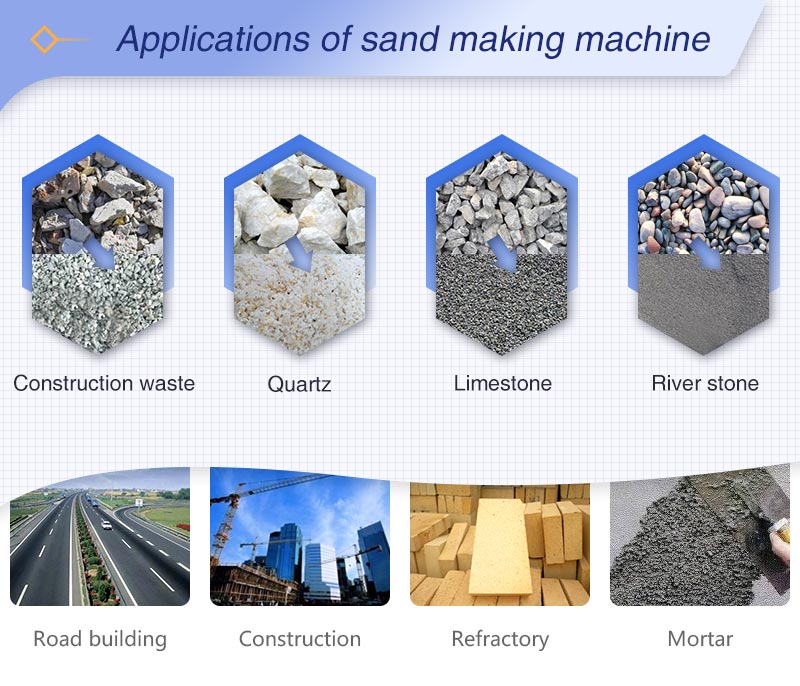

These three sand makers can efficiently process a variety of soft materials (limestone, talc, gypsum, kaolin, etc.), hard ore (granite, river pebbles, basalt, quartz, etc.), construction waste, etc.

The main application fields of the sand making machine are as follows,

Applications of sand making machine

Sand makers mainly utilize impaction and friction to process materials.

Taking the most popular VSI sand making machine as an example, the working principle of sand making machine is briefly introduced.

Here stone to stone and stone to iron are both used to complete the whole crushing.

VSI sand making machine uses advanced selective crushing and cleavage crushing to directly apply enough kinetic energy to materials. Then kinetic energy is converted into crushing energy by the impact.

Sand making machine working principle

Due to the best impact angle, the material is crushed along its natural grain surface and cleavage surface. The finished products have good shape with low material consumption.

1. The material enters the high-speed rotating wheel through the central feeding hole and is thrown out after obtaining tens of times the acceleration of gravity;

2. The thrown material hits the material that bounces off the counterattack plate and hits the material lining and counterattack plate together;

3. After bouncing in the crushing chamber many times with impact, friction, grinding, the qualified product is discharged from the discharge port.

So far, the whole sand making process is completed.

The three types of sand making machine of Fote have been welcomed by the international market.

From Zambia to Indonesia and Colombia, Fote offers satisfying sand solutions for a large number of customers.

At a silicon-sand production site in Indonesia, the HVI sand making machine has been praised by Mr. Hazami.

The HVI sand making machine has the new four-impeller structure with a deep cavity, which assures sand making and shaping.

He said:" I wanted to invest in a silica sand production line early last year. My friend introduced Fote Machinery to me. After detailed communication, I chose the solution provided by them. Running smoothly for more than a year, this sand making plant has left a good impression on me for its large output and high efficiency."

Details of the production line in Indonesia are as follows:

Processed material: silica

Feed size: about 25mm (after crushing)

Discharge size: below 5mm

Capacity: 50-100TPH

Working site of Fote HVI sand making machine

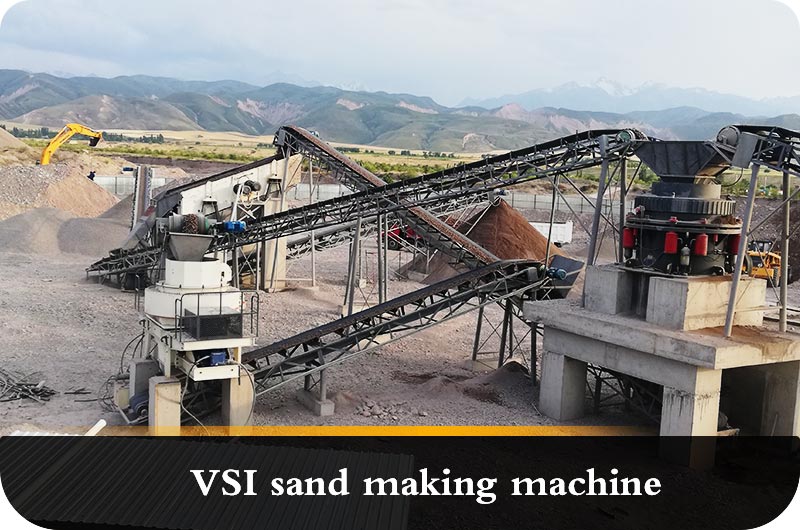

As one of the most popular sand machines, the VSI sand making machine is also known as the efficient vertical shaft impact crusher, which is designed based on customer needs and market status.

Mr. Monge in Philippine is an old customer of Fote. He has a say over the superior functions of VSI sand maker.

He runs an aggregate factory. The year before last year, Mr. Monge, who had introduced a crushing line from Fote, contacted our engineers again for a pebble sand production solution.

Details are as follows:

Feed size: 50cmX50cm

Discharge size: 0-5mm

Capacity: about 50TPH

Last week in the feedback, Mr. Monge told us, "As a regular customer, we trusted Fote as usual and the sand making plant did not disappoint us. The VSI sand machine time equipped produces excellent sand particles with reasonable grading. Our customers are very satisfied."

Working site of Fote VSI sand maker

Vertical shaft impact sand maker is one of the earliest sand making equipment in the market.

It adopts the famous crushing principle and technology of "stone to stone" from American Barmark.

Earlier this year, Mr. Smith in South Africa needed a concrete stone sand production line. After searching, Mr. Smith left his project requirements on the message board on Fote's website.

Within 24 hours Mr. Smith received a response from Fote engineers. Then he received the solution including the sand making plant price and flow chart.

The follows are the details of the vertical sand making machine:

Processed material: Concrete stone

Capacity: 50-100tph

Discharge size: 3mm, 9mm

Customer feedback

This was the first cooperation between Fote and us, and it was a happy experience. We were impressed by the professionalism and patience of Fote engineers.

The production line they provided is equipped with small, economical machines according to our working space and requirements.

The product is cubic, saving our storage space. And it's very easy to adjust the discharge size.

Working site of Fote vertical shaft impact sand making machine

As a direct manufacturer of sand making machines, Fote Machinery has been in the R&D of sand making equipment for 40 years.

Skilled Fote engineers keep learning advanced technology for developing generation after generation of sand machine combined with their own rich experience.

From free professional consultation to suitable sand production solution, from two-week delivery to the site installation guide of sand making plant, from life wearing parts to after-sales response at any time, Fote Machinery regards providing customer satisfaction service as the goal.

Any questions about sand making machine, please feel free to consult Fote engineer online or leave your requirements on the message board below. You can also send an email to quote@sinoftm.com and we will reply to you within 24 hours.

Shipment of Fote sand making machine

HVI Sand Making Machine

| Model | Sand Shaping | Sand Making | Sand Shaping | Sand Making | Motor Power(kw) |

| Max.Feeding Size(mm) | Throughput(t/h) | ||||

| HVI 0815 | <30 | <35 | 70-140 | 130-230 | 2×75 |

| HVI 0818 | <30 | <35 | 80-190 | 165-283 | 2×90 |

| HVI 0922 | <35 | <40 | 105-145 | 220-330 | 2×110 |

| HVI 0926 | <35 | <40 | 120-190 | 240-380 | 2×132 |

| HVI 1032 | <40 | <45 | 181-278 | 246-356 | 2×160 |

| HVI 1040 | <40 | <45 | 262-284 | 350-440 | 2×200 |

| HVI 1250 | <45 | <50 | 345-371 | 414-540 | 2×250 |

| HVI 1263 | <50 | <55 | 453-498 | 521-585 | 2×315 |

VSI Sand Making Machine

| Model | FTMVSI-7611 | FTMVSI-8518 | FTMVSI-9526 | FTMVSI-1140 | FTMVSI-1145 | FTMVSI-1150 | |

| Capacity (t/h) | Feed both at center and sides | 120-180 | 200-260 | 300-380 | 450-520 | 500-610 | 520-650 |

| Feed at center | 60-90 | 100-130 | 150-190 | 225-260 | 245-355 | 255-365 | |

| Max.feeding size(mm) | Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1150-1300 | 1150-1300 | |

| Double Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 400 | 4P 500 | |

| Overall dimension (L×W×H)(mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5100×2700×3300 | 5500×2700×3300 | 5500×2700×3300 | |

| Power supply | 380V 50HZ | ||||||

| Lubrication station | Double motor power of oil pump | 2×0.31Kw | |||||

| Safety assuance | Double oil pumps assure enough oil supply:automatic switch off with no oil stream or pressure,water cooling in summer,motor heating stare-up in winter. | ||||||

| Overall dimension (L×W×H) (mm) | 820×520×1270 | ||||||

| Power of oil tank heater | 2KW | ||||||

HVI sand making machine

| Model | Sand Shaping | Sand Making | Motor Power(kw) |

| Max.Feeding Size(mm) | |||

| HVI 0815 | <30 | <35 | 2×75 |

| HVI 0818 | <30 | <35 | 2×90 |

| HVI 0922 | <35 | <40 | 2×110 |

| HVI 0926 | <35 | <40 | 2×132 |

| HVI 1032 | <40 | <45 | 2×160 |

| HVI 1040 | <40 | <45 | 2×200 |

| HVI 1250 | <45 | <50 | 2×250 |

| HVI 1263 | <50 | <55 | 2×315 |

VSI sand making machine

| Model | Capacity(t/h) | |

| Feed both at center and sides | Feed at center | |

| FTMVSI-7611 | 120-180 | 60-90 |

| FTMVSI-8518 | 200-260 | 100-130 |

| FTMVSI-9526 | 300-380 | 150-190 |

| FTMVSI-1140 | 450-520 | 225-260 |

| FTMVSI-1145 | 500-610 | 245-355 |

| FTMVSI-1150 | 520-650 | 255-365 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat