By Fote Machinery Editer

By Fote Machinery Editer

River gravel, granite, basalt, bank gravel, bauxite, cement clinker, quartz silicon carbide,limestone, river stone, etc in hydropower, building material, highway, city construction, metallurgy, coal mining and so on.

Production Capacity:50-800TPH

Configuration:jaw crusher, impact crusher, vibrating feeder, circular vibrating screen, belt conveyor and other equipment.

River gravel refers to the non-angular natural grain with particle size of 2~60mm, which is transported by the flow of weathered rock for a long time. According to the particle size, gravel can be divided into boulders, coarse gravel and fine gravel. As a kind of purely natural stone with high application value, river gravel has formed long-term impact, extrusion and friction functions. The river gravel generally shows the color of black, white, yellow, red, green, and the like. River gravel has non-toxic, tasteless and non-bleaching characteristics.

With the wide distribution and high value, crushed river gravel can be used to make concrete and as an ideal building material. Therefore, how to crush river gravel effectively? The following will introduce you to a river gravel crushing production line

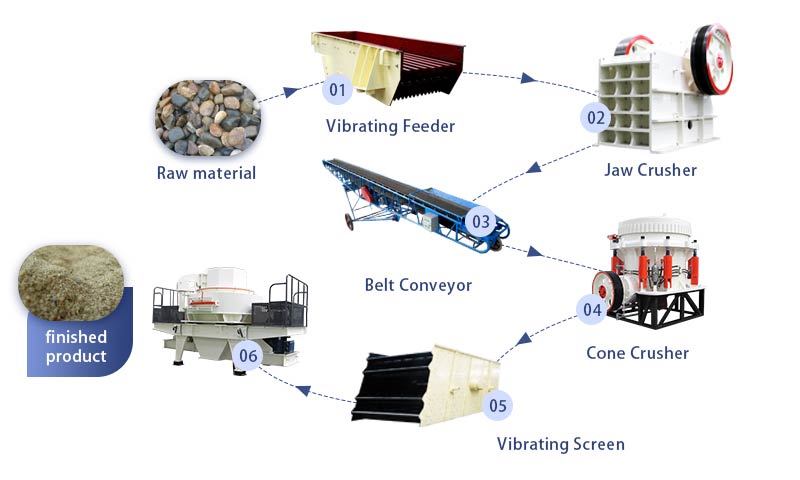

According to the nature of river gravel, Fote Machinery has developed a set of simple and reasonable river gravel crushing plant, which is mainly composed of jaw crusher, impact crusher, vibrating feeder, circular vibrating screen, belt conveyor and other equipment.

The raw material passed through the silo, is uniformly fed by the vibrating feeder, and is sent to the jaw crusher for primary crushing.

The belt conveyor evenly conveys the broken material to the cone crusher for fine crushing and screening by circular vibrating screen after crushing.

The medium-size material is sent to a sand making machine to be finely crushed, the round vibrating screen is used for screening, and the large-particle material is returned to the sand making machine to be broken again.

After the screening operation, the qualified materials will be transported to the finished product inventory.

How to Configure the River Gravel Crushing Production Line?

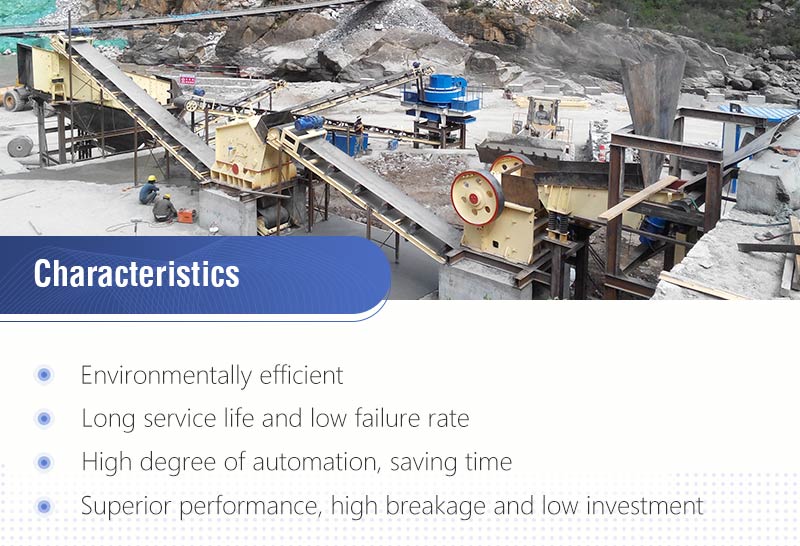

In recent years, the vigorous development of river gravel sand production line is due to the fact that most manufacturers have equipped fine sand recovery equipment to improve the finished sand quality of the whole sand production line. Due to its excellent performance, smooth production, and more importantly, the reason for high output, the user starts to invest in construction. Then in the investment river gravel sand production line, how to configure the user can get higher profits, now gives you some suggestions on several key points:

As a result of the user's investment in such a large project, it is certainly necessary to have better results through the identification of the various program. By comparing and analyzing different configuration schemes, users can choose more suitable one.

Users must have their own production line standards when building river sand and stone production lines. Many users will mistakenly think that if they want to have a large output, they have to buy a large model of crushing machine. In fact, this is completely wrong. Buying a suitable crushing machine can not only save trouble, but also be the basis of reasonable investment.

The principle is the minimum standard, and the river gravel sand production line is a complete river gravel sand making technology.In the investment, user must be based on the rationality principle of the process, and the advanced principle. Why do you say that? Rationality means that the possibility of investment and construction of river gravel stone production line is unreasonable when the production line is unreasonable, which is not only a waste of time, but also is not conducive to the investment of users. Advanced nature means that the sand production line can get high returns and the rapid recovery of use cost. Therefore, users must remember to follow the principles in the river sand production line investment process.

Online Chat

Online Chat