As a main source of artificial sand used in construction, quarry rock crusher can be equipped with various crushing equipment according to the production mode. To meet different particle requirement of small, medium and large scaled mining plants and supply high-quality aggregates, customized solutions from specialized FTM engineers are available. We have a whole line or separate crusher machine for sale, including Jaw Crusher, Impact Crusher, Cone Crusher, Sand Making Machine, Sand Washer, etc. The hot-sale quarry stone crusher capacity includes 1-30tph, 30-50tph, 50-100tph, 100-300tph, 300-500tph.

Quarry rock crusher is widely used as the primary, secondary and tertiary crushing equipment for the crushing of limestone, concrete, aggregate, granite, basalt, copper ore, dolomite, quartz, iron ore, and other mineral and rocks in a quarry, construction, mining, road construction, and other industries.

Quarry Stone Crusher Application

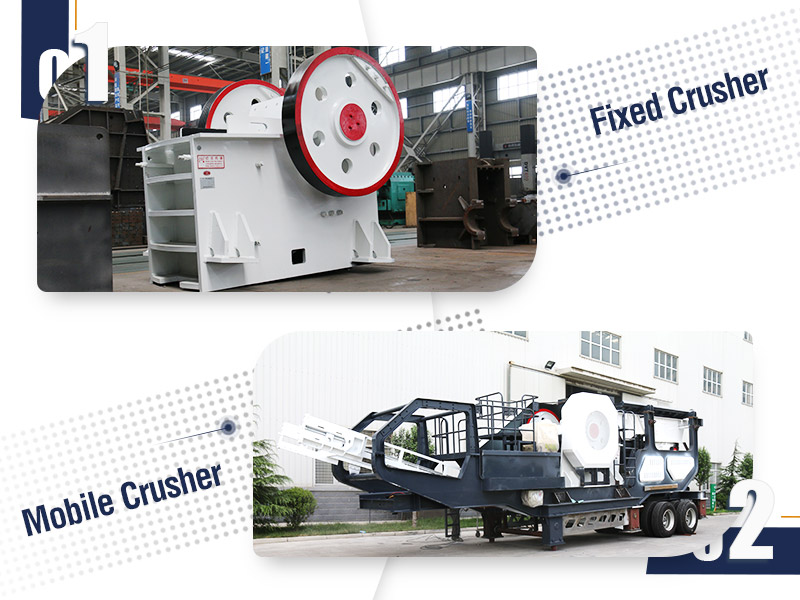

Fote Machinery has stationary stone crusher and mobile stone crusher type for your choice.

As primary crushing equipment, jaw crusher can be together with cone crusher, which is particularly suitable for the process of high-hardness materials. The layered stage crushing process makes the finished product on uniform size and good shape.

Jaw Crusher+Cone Crusher

This group is mainly used for medium and small hardness material crushing. The finished products are extensively used in construction with good value for money. Besides, the investment of this group is less than the above combination.

Jaw Crusher+Impact Crusher

Hammer crusher can be used as one-step crushing machine to simplify the entire crushing process, which can be directly fed materials. And together with the sand making machine, this grouped machines can produce particles with fine shape.

Hammer Crusher+Sand Making Machine

Mobile stations can carry a variety of crushers. In addition to the original benefits of the crusher, mobile types have advantages of flexible work and no need to re-install in another working site. So, it is convenient to have a conversion of different workplaces.

Fixed Crusher VS. Mobile Crusher

There are factors to be taken into consideration when select crushers. On one hand, they should choose machines according to the material hardness, the production capacity, the input and output size required, and so on. While on the other, except the price, the size of the manufacturer, the service of the businessman, etc. should be considered.

In South Africa, FTM Jaw Crusher and Impact Crusher are combinedly used in the limestone production line with a production capacity of 100TPH, the input size of less than 700mm and the output size of 15-40mm.

Quarry Rock Crusher Customer Site

Adopting advanced technology from German, the U.S., and other European countries and having been cooperated with many universities and colleges, FTM supplies types of crusher equipment and other mining equipment customized with 100% factory price and professional process. We are here ready to supply free consultation.

Model | Feed opening (mm) | Max.feeding size(mm) | Adjusting range of discharge opening (mm) | Processing capacity (t/h) | Rotation speed of eccentric shaft(r/min) | Motor power (kw) | Total weight (t) | Dimensions (L×W×H) (mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-21 | 300 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 275 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 250 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 250 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 15.6 | 2720×1950×1600 |

Model | Max.feeding size(mm) | Adjusting range of discharge opening (mm) | Processing capacity (t/h) |

| PE-150×250 | 125 | 10-40 | 1-3 |

| PE-200×300 | 180 | 15-50 | 2-6 |

| PE-200×350 | 180 | 18-70 | 3-10 |

| PE-250×400 | 210 | 20-60 | 5-21 |

| PE-400×600 | 340 | 40-100 | 16-64 |

| PE-500×750 | 425 | 50-100 | 40-110 |

| PE-600×750 | 500 | 150-200 | 80-240 |

| PE-600×900 | 500 | 65-160 | 50-160 |

| PE-750×1060 | 630 | 80-140 | 110-320 |

| PE-800×1060 | 640 | 130-190 | 130-330 |

| PE-830×1060 | 650 | 160-220 | 150-336 |

| PE-870×1060 | 660 | 200-260 | 190-336 |

| PE-900×1060 | 685 | 230-290 | 230-390 |

| PE-900×1200 | 750 | 95-165 | 220-380 |

| PE-1000×1200 | 850 | 195-265 | 315-500 |

| PE-1200×1500 | 1020 | 150-350 | 400-800 |

| PE-1500×1800 | 1200 | 220-350 | 500-1000 |

| PEX-150×750 | 120 | 18-48 | 8-25 |

| PEX-250×750 | 210 | 25-60 | 13-35 |

| PEX-250×1000 | 210 | 25-60 | 16-52 |

| PEX-250×1200 | 210 | 25-60 | 20-61 |

| PEX-300×1300 | 250 | 20-90 | 16-105 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat