Email (quote@sinoftm.com), we will reply to you within 24 hours

Depth: 750-3500mm

Effective Volume: 0.26-30m³

The mixer is also called agitating tank or a mixing tank. Mixing drum is necessary equipment which is driven by an electric motor with v-belt to rotate the impeller, mixing the drug and pulp thoroughly and evenly, increasing the reaction time and strengthen the quality of drug reaction. This machine belongs to powered mixer, and is suitable for mining industry, also can be used for all kinds of chemical industry agitator. Mixing tank is also suitable for all kinds of metal ore, mainly used for mixing medicament and pulp before flotation, also can be used for stirring other non-metallic minerals. It can be used when the concentration is less than 30% (by weight) and the particle size of the fixed component is less than 1mm. It is in the form of flat bottom barrel radial circulation spiral impeller mechanical agitation type.

Mixer consumables: impeller, stator

Mixing tank is a kind of essential equipment to fully mixing the reagent and the ore pulp, increasing the reaction time of the reagent and strengthening the quality of the reagent reaction. This machine is suitable for ore beneficiation industry, and can also for stirring the ingredients in all various industries.

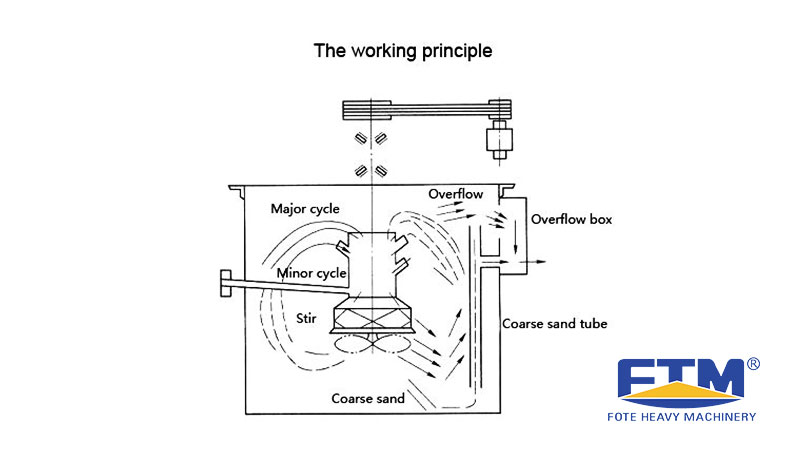

When the machine works, the slurry and reagents will have large and small circulation under the rotation of the impeller, and they will be evenly mixed, and the mixed suspension will be discharged from the overflow port.

The machine is arranged in front of the flotation machine to mix reagents and pulp thoroughly. And the machine is suitable for pulp with mixed density those less than 3.5 and flotation reagent with density less than 30%.

Henan is an important mixer production base. Here mainly for the users to recommend a good mixing tank manufacturer in henan – Fote Machinery. It not only has a mature stirring tank production process, and the production facilities are complete, FTM provides users with good equipment exquisite technology, strong stability, and convenient operation, which can make production more time saving, labor saving, and help users in the operation of higher profits.

| Category | Specification Model |

Dimensions | Effective cubage(m³) |

Rotate speed(r/min) |

Motor power (kw) |

Dimensions (L×W×H) (mm) |

Total weight (kg) |

|

| Diameter (mm) |

Height (mm) |

|||||||

| Agitating tank |

XB-10×10 | 1000 | 1000 | 0.58 | 390 | 1.5 | 1130×1130×1521 | 1050 |

| XB-12×12 | 1200 | 1200 | 1.18 | 390 | 2.2 | 1130×1330×1721 | 1160 | |

| XB-15×15 | 1500 | 1500 | 2.2 | 280 | 3.0 | 1750×1640×2190 | 1270 | |

| XB-20×20 | 2000 | 2000 | 5.6 | 210 | 5.5 | 2380×2160×2850 | 1700 | |

| XB-25×25 | 2500 | 2500 | 11.2 | 190 | 7.5 | 2990×2720×3540 | 3500 | |

| XB-30×30 | 3000 | 3000 | 19 | 140 | 18.5 | 4030×3270×3010 | 5200 | |

| XB-35×35 | 3500 | 3500 | 29 | 230 | 30 | 3920×3740×4970 | 6630 | |

| XB-40×40 | 4000 | 4000 | 45 | 210 | 37 | 4520×4320×5570 | 7830 | |

| Lifting type |

XBT-10×15 | 1000 | 1500 | 1 | 510 | 2.2 | 1130×1130×2070 | 1250 |

| XBT-15×20 | 1500 | 2000 | 2.9 | 400 | 4 | 1636×1768×2785 | 1677 | |

| XBT-20×20 | 2000 | 2000 | 5.6 | 312 | 11 | 2180×2220×3015 | 3100 | |

| High- efficiency leaching tank |

XF-20×20 | 2000 | 2000 | 7.07 | 82.5 | 1.5 | 2032×2032×3595 | 2400 |

| XF-25×30 | 2500 | 3000 | 13.5 | 57.6 | 2.2 | 2532×2532×4152 | 3670 | |

| XF-30×30 | 3000 | 3000 | 22.97 | 50.0 | 2.2 | 3180×3180×4673 | 5340 | |

| XF-35×40 | 3500 | 4000 | 35.6 | 41.0 | 4.0 | 3685×3685×5314 | 7140 | |

| XF-40×45 | 4000 | 4500 | 52.78 | 33.5 | 4.0 | 4185×4185×5814 | 9300 | |

| XF-45×50 | 4500 | 5000 | 74.75 | 33.5 | 5.5 | 4685×4685×6466 | 10500 | |

| XF-50×56 | 5000 | 5600 | 102.1 | 30.6 | 5.5 | 5185×5185×6975 | 12300 | |

| XF-55×60 | 5500 | 6000 | 135.4 | 24.4 | 7.5 | 5670×5670×7569 | 13500 | |

| Category | Specification Model |

Effective cubage(m³) |

Rotate speed(r/min) |

| Agitating tank |

XB-10×10 | 0.58 | 390 |

| XB-12×12 | 1.18 | 390 | |

| XB-15×15 | 2.2 | 280 | |

| XB-20×20 | 5.6 | 210 | |

| XB-25×25 | 11.2 | 190 | |

| XB-30×30 | 19 | 140 | |

| XB-35×35 | 29 | 230 | |

| XB-40×40 | 45 | 210 | |

| Lifting type |

XBT-10×15 | 1 | 510 |

| XBT-15×20 | 2.9 | 400 | |

| XBT-20×20 | 5.6 | 312 | |

| High- efficiency leaching tank |

XF-20×20 | 7.07 | 82.5 |

| XF-25×30 | 13.5 | 57.6 | |

| XF-30×30 | 22.97 | 50.0 | |

| XF-35×40 | 35.6 | 41.0 | |

| XF-40×45 | 52.78 | 33.5 | |

| XF-45×50 | 74.75 | 33.5 | |

| XF-50×56 | 102.1 | 30.6 | |

| XF-55×60 | 135.4 | 24.4 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat