By Fote Machinery Editer

By Fote Machinery Editer

Lithium, copper, zinc, lead, nickel, gold and other non-ferrous metals, ferrous and non-metal.

Production Capacity:0.18-7 (m ³/min)

Configuration:Jaw crusher, ball mill, sprial classifier, flotation machine, concentrator machine and dryer machine.

Lithium ore is a kind of metal ore formed by chemical reaction in sedimentary rocks for a long time. The comprehensive utilization value of this mine is very high, and it is used as a high-end metal in chemical industry, metallurgy, aerospace and other fields, which plays a vital role in the development of modern science and technology.

For the processing of lithium ore, in addition to using separate equipment for processing operations, but also can use lithium ore processing technology for production and manufacturing. However, facts fully prove that lithium ore produced by lithium ore processing technology is easier to meet the actual needs of users. The equipment and process flow of lithium ore processing technology are described systematically as following.

Lithium ore processing process requires a lot of equipment;systematically speaking, it has three types of equipment: crushing equipment, grinding equipment, flotation equipment. On this basis, some auxiliary devices are also added, which are described in detail below:

The first type of equipment needed for lithium processing is the crushing equipment. According to the characteristics of the lithium mine and the processing technology, our company chooses jaw crusher and cone crusher to carry out the primary and secondary crushing of lithium ore. So far, the discharge particle size of lithium ore can enter the ball mill smoothly, so as to ensure the smooth operation of the whole process.

Jaw Crusher and Cone Crusher

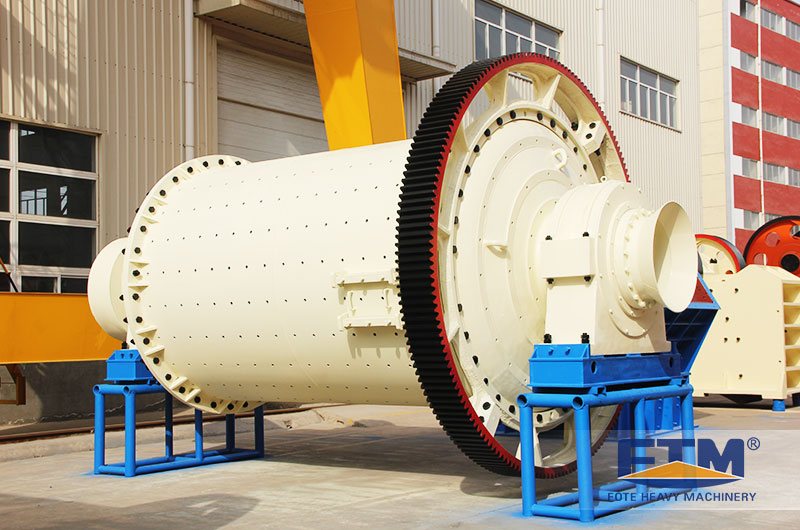

Grinding equipment generally refers to the ball mill, and it is a professional equipment for the grinding of lithium ore. In the manufacturing process in Fote Machinery, precise design has been carried out, especially in the selection of core components. We use the motor with reliable performance, and high-quality motor is an important part to improve the production capacity of the equipment, so the equipment can guarantee the realization of the production capacity of the equipment in the process of application.

Ball Mill

Flotation machine is the equipment to realize flotation process, which plays a crucial role in the process of lithium ore processing. In order to further improve the flotation effect, the equipment configuration of this process must be a reasonable choice of equipment model, and a reasonable flotation model can improve the flotation accuracy of lithium ore.

Flotation Machine

Auxiliary equipment mainly includes classifier, dryer, vibrating feeder, vibrating screen, mixing bucket, etc., only by the reasonable integration of these auxiliary equipment in the lithium mineral processing line, it can constitute a complete lithium mineral processing line. Therefore, these auxiliary machines are indispensable equipment in the process, in the whole lithium mineral processing production line also plays a crucial role.

From the above selection of equipment, lithium ore processing process roughly flow: crushing → grinding → flotation. But according to the impurity content and moisture content of the material, also use vibration screen, dryer and other equipment. The following is a systematic introduction of its detailed process:

Firstly, put the original lithium ore into the stock bin, after the primary election into the vibration feeder, thus making full preparations for the subsequent crushing task.

Secondly, the lithium ore in the feeder is transported through the conveying device to the crushing equipment for crushing. In this process, it is necessary to use a crusher with a larger crushing ratio and a larger production capacity, only in this way to ensure that the production efficiency of the whole process can meet the actual requirements.

Then, after the crusher processing of lithium ore into the ball mill for grinding, so that the lithium ore particle size are more uniform and fine. After the grinding, it enters the flotation machine. In this process, it must be equipped with reasonable flotation agents, so as to achieve the ideal flotation effect.

Finally, If the processing of lithium ore moisture content exceeds the standard, but also use a dryer for drying. This process can not only reduce the moisture content of materials, but also greatly help improve the sophistication of lithium ore.

With the most reliable equipment quality, most reasonable price and the most complete services, Fote Machinery is recognized as one of the most famous lithium ore processing equipment manufacturers in China. The complete and comprehensive service system of Fote Machinery is unmatched in the mining market. What's more, we provide equipment upgrading service to extend the equipment service life.

Fote Machinery will give you most reasonable guide and design. Welcome to choose Fote Machinery.

Online Chat

Online Chat