Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Limestone, coal gangue, granite, bluestone, construction waste, cobble, pebble, basalt, iron ore, quartz, calcite, concrete, cement clinker and some metal, etc.

Adopting advanced international technology and learning from working experience, FTM engineers keep doing R&D to optimize crushing machine. As a kind of stone crusher, the impact crusher machine is widely used for all coarse, medium and fine materials crushing (granite, limestone, concrete, etc.) which are of less than 500mm side length and less than 350MPa compressive strength. Discharge particle size is adjustable and different specifications of FTM impact crushers are available.

Fote Impact Crusher

Different models of Fote impact crusher can be applied to different areas. For example, CI series impact crusher is utilized to first, second and third stage crushing, that is, for coarse, medium and fine crushing. HX series impact crusher is mainly for the first and second stage crushing. That is the coarse and fine crushing.

Generally, Fote impact crusher is used extensively for crushing pebble, limestone, granite, quartz, concrete, basalt and other minerals in the artificial aggregate production and ore crushing in railway, highway and construction industry, etc.

Impact crusher machine is a stone breaking machine using the impact force to the materials mainly of medium hardness. When an impact crusher works, the rollers rotate at a high speed powered by the motor. The materials get huge energy from the hammers on rotators and are crushed for the first time. Then they are thrown to the impact plates for the second-time crushing. Lastly, they are sprung back to the hammer and get another impaction of the third crushing. Thus, a crushing process is completed.

Working Principle of Impact Crusher

FTM impact crusher is mainly composed of impact plates, rotators, hammers, adjustment devices, etc. After the structural adjustment, the FTM impact crusher gets a functional improvement.

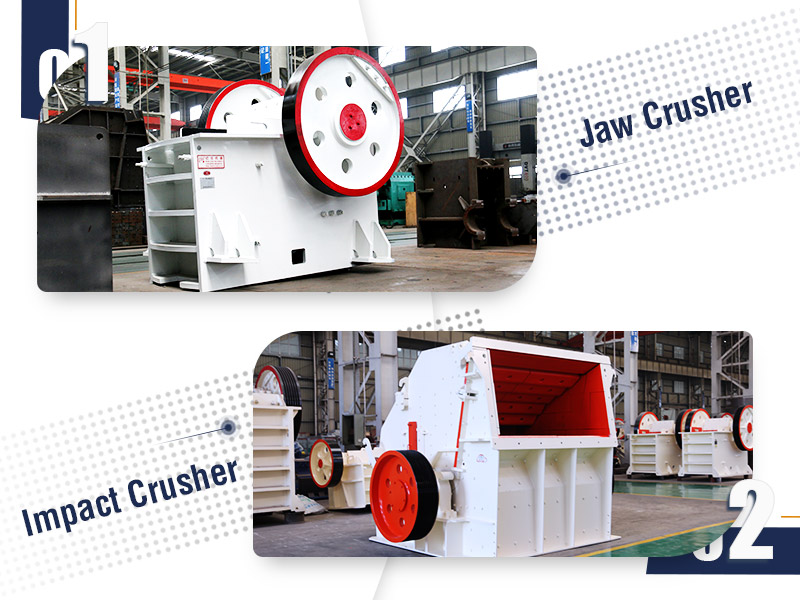

| Impact Crusher | Jaw Crusher | |

| Inset Size(mm) | 400x730-1260x2040 | 150x250-300x1300/950x1250 |

| Feed Size(mm) | 300-1300 | 125-1200 |

| Capacity(T/H) | 30-2000 | 1-1160 |

| Highlight | Large Impact Force; Good Particle Shape | Big Crushing Ratio; Even Particle Shape |

Table of Some Specifications of Jaw Crusher and Impact Crusher

Here in the table, we can see it clearly that impact crusher has a larger inset opening size and different working principle of impaction. While the jaw crusher has more models with different inset opening sizes, which means that jaw crusher is adaptable for different sizes of mines and plants. Usually, jaw crusher is used in the primary crushing process, while impact crusher is for the secondary crushing process. Combined with vibrating screen and vibrating feeder, these two crushers are used in the stone crushing plant. With sand making machine, sand washer, screen and feeder, jaw crusher can be used in sand making plant.

Impact Crusher VS Jaw Crusher

FTM CI series Impact Crusher in France in a limestone production line with a capacity of 50TPH, the feeding size of 300mm and the discharging size of 15mm, 30mm.

Different Angles of FTM Impact Crusher in Customer Site

Fote Machinery has superior-quality impact crusher for sale. Our impact crusher is priced based on different models. We have fixed impact crusher as well as mobile impact crusher for sale, the latter of which includes tracked type and wheel type. Based on the mine environment, you can choose a fixed impact crusher for its lower cost but fewer flexibility; or you can choose a mobile impact crusher for its flexibility but a little higher cost. However, the impact crusher price of our company is the most favorable. If you want to find out more details about our products, please contact us!

| Model | Specification (mm) | Feed Opening (mm) | The Maximum Feeding Size (mm) | Capacity (t/h) | Power (kw) | Overall Dimension (L×W×H) (mm) | Total Weight (t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

| Model | Feed Opening (mm) | The Maximum Feeding Size (mm) | Capacity (t/h) |

| Φ1000×700 | 400×730 | 300 | 30-70 |

| Φ1000×1050 | 400×1080 | 350 | 50-90 |

| Φ1250×1050 | 400×1080 | 350 | 70-130 |

| Φ1250×1400 | 400×1430 | 350 | 80-180 |

| Φ1320×1500 | 860×1520 | 500 | 100-280 |

| Φ1300×2000 | 993×20000 | 500 | 140-380 |

| Φ1500×2000 | 830×2040 | 700 | 200-550 |

| Φ1800×2000 | 1260×2040 | 800 | 400-800 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat