Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Limestone, granite, cobble, dolomite, bluestone, basalt, sandstone, gravel, pebble, iron ore, construction waste, cement clinker, artificial sand, dry mortar and all kinds of stones and non-ferrous metal ores.

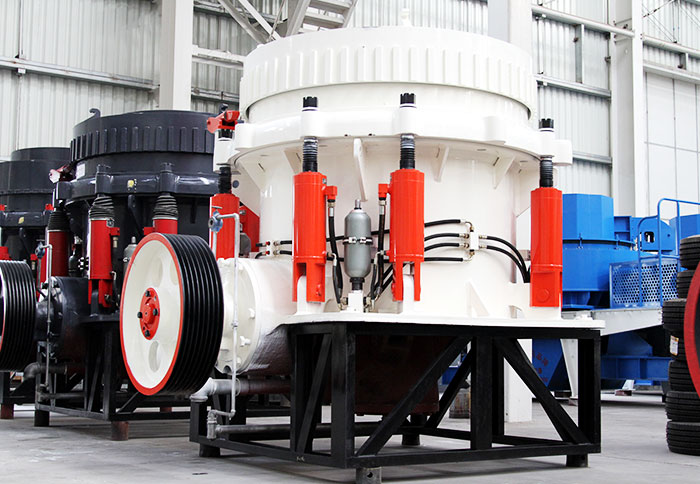

Fote hydraulic cone crusher is a new type of cone crusher taking the advantages of single cylinder hydraulic cone crusher and PSG cone crusher. With advanced technology and optimized design, GYS hydraulic cone crusher is of improved performance, crushing capacity and working efficiency. Better eccentricity and crushing frequency are employed, which increases the quantity of the fine grains in the finished products. The content of particles in the outset that is smaller than the edge can reach 80%, which can improve the follow-up processing and decrease the comprehensive energy consumption.

Hydraulic cone crusher is widely used in the mining industry, cement industry, and other fields. Due to its strict requirements in particle size, high requirement of finished product rate and a high degree of automation, it is a favorable choice in the stone crushing plant.

Video for Workshop of Hydraulic Cone Crusher

Hydraulic cone crusher is widely used in the building industry, metallurgy industry and mineral industry for the medium and fine crushing of materials with intermediate and high hardness, such as iron ore, non-ferrous metal ore, granite, limestone, basalt, sandstone, gravel, pebble, etc.

Application of Hydraulic Cone Crusher

Large Hydraulic Cone Crusher

As a new type of cone crusher, hydraulic cone crusher is protected by hydraulic safety devices when overloading happens. As for the crushing process, it is completed by a fixed cone and the cyclic-moved cone. When a hydraulic cone crusher is started, the horizontal axis is driven by a motor. Two different sized wheels make the eccentric bushing rotate through the axis. The cone axis rolls jiggingly and the crushing wall goes near to and far away from the fixed cone wall regularly. The materials fallen between the fixed cone and movable cone is pressed and impacted constantly to the qualified size. Those qualified particles fall down under the effect of gravity and are belched out.

Working Principle of Hydraulic Cone Crusher

1. These two kinds of hydraulic cone crusher can both be used for medium and fine crushing of materials with high and intermediate hardness.

2. The automatic control system of PLC+ touch screen is adopted both by single cylinder cone crusher and multi cylinder cone crusher, which assures the stable and safe operation of the machine.

3. No need to fill the rolling mortar wall. So it is easy and fast to replace this part.

1. Single cylinder cone crusher is modeled as SC-S, which is for medium crushing, and SC, which is for fine crushing. There is one model, HP, of a multi cylinder cone crusher.

2. The single cylinder cone crusher is of a Max. the production capacity of 2181 TPH, while the multi cylinder cone crusher can reach a little lower production capacity of 1100 TPH.

Single Cylinder Hydraulic Cone Crusher VS Multi Cylinder Hydraulic Cone Crusher

FTM Hydraulic Cone Crusher in Nigeria for granite and calcite marble crushing with production capacity of 100TPH, feeding size of 700mm and discharging size of 0-10mm, 10-15mm, 15-25mm, and 25-40mm.

Installation and Working Site of Hydraulic Cone Crusher

As a specialized cone crusher manufacturer, Fote Machinery supplies professional hydraulic cone crusher, spring cone crusher and so on. Fote hydraulic cone crusher price is more reasonable in the mining equipment market. A free consultation is ready here for you!

| Model | Cavity | Diameter of large end of crushing cone (mm) |

Width of Feeding Opening(mm) |

Max. feeding size (mm) |

Adjusting Range of Discharge Opening (mm) |

Processing capacity(t/h) |

Main motor power(kw) |

Weight of Main Machine (t) |

| FTMHP200 | C1 | 900 | 210 | 178 | 22~38 | 160~250 | 160 | 10.1 |

| C2 | 155 | 132 | 18~38 | 145~250 | ||||

| C3 | 130 | 110 | 14~38 | 120~250 | ||||

| F1 | 118 | 100 | 12~25 | 108~210 | ||||

| F2 | 90 | 76 | 10~25 | 81~210 | ||||

| F3 | 70 | 60 | 8~25 | 72~210 | ||||

| FTMHP300 | C1 | 1100 | 235 | 200 | 26~45 | 230~445 | 220 | 17.8 |

| C2 | 211 | 180 | 20~45 | 200~445 | ||||

| C3 | 135 | 115 | 16~45 | 180~445 | ||||

| F1 | 124 | 105 | 14~25 | 160~220 | ||||

| F2 | 96 | 82 | 12~25 | 140~220 | ||||

| F3 | 70 | 60 | 8~25 | 120~220 | ||||

| FTMHP400 | C1 | 1400 | 330 | 280 | 26~51 | 270~630 | 315 | 25 |

| C2 | 200 | 170 | 22~51 | 243~630 | ||||

| C3 | 152 | 130 | 16~51 | 210~630 | ||||

| F1 | 135 | 115 | 12~25 | 162~370 | ||||

| F2 | 106 | 90 | 10~25 | 126~370 | ||||

| F3 | 80 | 68 | 8~25 | 104~370 | ||||

| FTMHP500 | C1 | 1500 | 335 | 285 | 32~51 | 365~790 | 400 | 34.1 |

| C2 | 229 | 190 | 25~51 | 328~790 | ||||

| C3 | 180 | 152 | 19~51 | 280~790 | ||||

| F1 | 152 | 130 | 13~25 | 202~450 | ||||

| F2 | 124 | 105 | 10~25 | 158~450 | ||||

| F3 | 88 | 75 | 8~25 | 122~450 | ||||

| FTMHP800 | C1 | 2000 | 385 | 326 | 32~51 | 616~1100 | 630 | 69.2 |

| C2 | 350 | 298 | 25~51 | 522~1100 | ||||

| C3 | 280 | 238 | 16~51 | 380~1100 | ||||

| F1 | 160 | 136 | 13~25 | 328~730 | ||||

| F2 | 120 | 102 | 10~25 | 270~730 | ||||

| F3 | 90 | 77 | 8~25 | 166~730 |

| Model | Cavity | Diameter of large end of crushing cone (mm) |

Processing capacity(t/h) |

| FTMHP200 | C1 | 900 | 160~250 |

| C2 | 145~250 | ||

| C3 | 120~250 | ||

| F1 | 108~210 | ||

| F2 | 81~210 | ||

| F3 | 72~210 | ||

| FTMHP300 | C1 | 1100 | 230~445 |

| C2 | 200~445 | ||

| C3 | 180~445 | ||

| F1 | 160~220 | ||

| F2 | 140~220 | ||

| F3 | 120~220 | ||

| FTMHP400 | C1 | 1400 | 270~630 |

| C2 | 243~630 | ||

| C3 | 210~630 | ||

| F1 | 162~370 | ||

| F2 | 126~370 | ||

| F3 | 104~370 | ||

| FTMHP500 | C1 | 1500 | 365~790 |

| C2 | 328~790 | ||

| C3 | 280~790 | ||

| F1 | 202~450 | ||

| F2 | 158~450 | ||

| F3 | 122~450 | ||

| FTMHP800 | C1 | 2000 | 616~1100 |

| C2 | 522~1100 | ||

| C3 | 380~1100 | ||

| F1 | 328~730 | ||

| F2 | 270~730 | ||

| F3 | 166~730 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat