Email (quote@sinoftm.com), we will reply to you within 24 hours

Warranty Period: 1 Year

Raw Materials: Gypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc.

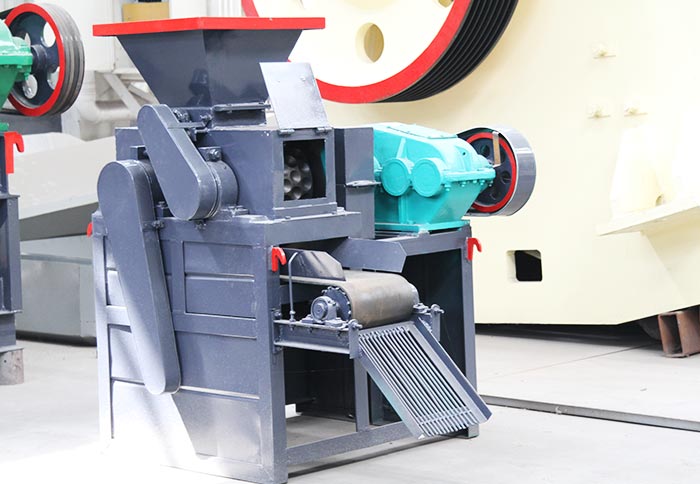

Gypsum briquette machine is mainly used to suppress desulfurization gypsum powder, and the pressed balls can be used as a retarder in cement plant. In recent years, its application in building material industry is very extensive. It has characteristics of high molding pressure, easy demoulding, high-efficiency, low energy consumption, low failure rate, and convenient repair. It has five types according to the yield. The direct pressing without subsequent drying process is more conducive to the existing production process of convergence and transformation, which has high forming strength. It is suitable for all kinds of transportation, so as to reduce the packaging cost.

Gypsum compactor and its supporting equipment can compress desulfurized gypsum powder into disposable ball products without any help of adhesive. Through the characteristics of high yield and good hardness, it has been put into production in many power plants and cement plants in China with good results.

Gypsum briquetting machine can press desulfurized gypsum powder, phosphor gypsum and natural gypsum into balls at one time without adding any binder, which has high ball forming rate, high yield, high strength, convenient transportation and storage. It has been put into use in many power plants and cement plants put into operation.

Features of Gypsum Briquetting Machine

Finished Shapes of Briquetting Machine

Gypsum compactor consists of two parts: feed part and drive part. The feeding part mainly ensures the uniform feeding of the material into the double rollers through quantitative feeding, while the rear part of the driving device is equipped with a hydraulic device.

Hydraulic protection is driven by hydraulic pumps, which move the piston shaft. The front end of the piston rod supports the bearing block to meet the requirements of production pressure.

The gypsum press obtains power from the hydraulic circuit, the hydraulic control valve and the accumulator. The material enters the feeder hopper quantitatively through the storage box and then enters the space between the two rollers after the adjustment gate of the hopper is changed. When the forming pressure changes from low to high and reaches the maximum pressure at the double roller connector, the roll material is run in reverse at a constant speed. When passing through the production line, the material is in the state of ball separation, and the molding pressure is rapidly reduced, thus completing the separation process.

Fote Machinery is professional in the production of gypsum briquetting machines, which include flue gas desulfurization gypsum briquetting machine and phosphogypsum briquetting machine. Currently, many power plants and cement plants have put gypsum briquetting machines into use, and the effect is very good. We have successfully signed the implementation of desulfurization gypsum briquetting plant with many customers, so as to realize the waste recycling purpose. If customers want to know more information about our professional desulfurization gypsum briquetting plant, you can visit the production sites.

| Model | Roller Diameter (mm) | Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) | Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat