Email (quote@sinoftm.com), we will reply to you within 24 hours

Processed Materials: Granite, basalt, limestone, pebble, cement clinker, quartz sand, iron ore, bauxite, construction waste, glass and some metal, etc.

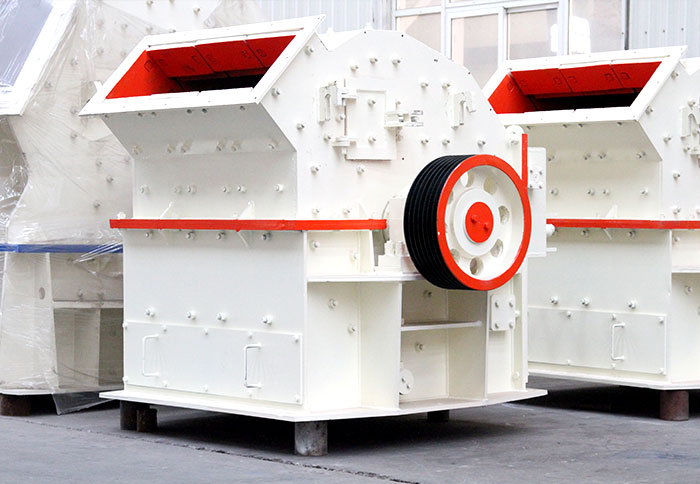

Fote fine crusher, also known as tertiary crusher, is one kind of crusher machine combining the working principle of impact crusher and hammer crusher with higher efficiency and lower energy consumption of 50% than traditional fine crusher. It is extensively used for the medium and fine crushing of materials that are brittle and of lower hardness, such as pebble, cement clinker, quartz, etc. in the refractory industry, metallurgy industry and other industries. Fote supplies fine crusher with simplified structure and high efficiency.

Fine crusher is also known as tertiary crusher, which is widely used for the fine crushing or sand making of granite, basalt, limestone, pebble, cement clinker, iron ore, bauxite, and other minerals. This crusher machine is suitable for high-quality sand and stone production. For example, it can be used as fine aggregate crusher equipment in highway and railway, quartz sand or silica sand making machine in the construction industry, cement industry, refractory industry, metallurgy industry, etc.

Application of Fine Crusher

Fine crusher is one kind of crushing equipment that can be utilized to make artificial sand. Therefore, it is called the third-generation sand maker or fine powder crusher.

Comparison of Materials before Crushing and After Crushing by Tertiary Crusher

Fine crushing machine is mainly composed of motor, driving system, main engine, etc. Fine Crusher runs based on the same principle that impact crusher does. When fine crusher works, rollers are rotated at high speed by motor. Stage crushing is adopted. Materials fed into the first crushing chamber get crushed with the hammers on the rollers and impacted to the chamber wall. Next, materials that have been firstly crushed fall into the second fine crushing chamber to have a further crushing here to qualified particles. When crushing finished, they are belched out.

In Ethiopia, FTM Fine Crusher is used for quarry limestone with a capacity of 50TPH, the input size of 250-300mm and the output size of 19mm.

Found on 20th, June, 1986, FTM has witnessed and experienced most of the development of the mining machine in China. So far, FTM has established three R&D branches as well as three centralized factories. Has introduced advanced technology from German, America, Japan, Australia, etc., Fote is keeping hard work to supply products with high quality and good service at the lowest cost. FTM is your satisfactory choice!

Fine Crusher in Fote Factory

|

PXJ tertiary impact crusher

|

Rotorø×Width

(mm) |

|||||||

|

Specification

|

800×400

|

800×600

|

800×800

|

1010×1010

|

1200

×1200 |

1400

×1400 |

1600

×1600 |

1800

×1800 |

|

Feed opening size(mm)

|

400×185

|

500×250

|

550×300

|

1000×350

|

1200

×450 |

1500

×500 |

1600

×550 |

1800

×800 |

|

Feeding size (mm)

|

<120

|

<180

|

<180

|

<180

|

<180

|

<190

|

<190

|

<190

|

|

Discharging size (mm)

|

0-10

|

0-10

|

0-10

|

0-10

|

0-10

|

0-10

|

0-10

|

0-10

|

|

Adjustable range of discharge opening (mm)

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

|

Cement Clinker(t/h)

|

10-30

|

1040

|

20-45

|

25-55

|

35-90

|

50-150

|

85-210

|

125-270

|

|

Limestone(t/h)

|

18-45

|

23-55

|

28-65

|

35-75

|

45-110

|

50-150

|

95-260

|

140-310

|

|

Power(kw)

|

4P 37KW

|

4P 45KW

|

4P 45KW

|

4P 55KW

|

6P 110KW

|

6P 160KW

|

4P 250KW

|

4P 315KW

|

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

| Specification |

Limestone (t/h) |

| 800×400 | 18-45 |

| 800×600 | 23-55 |

| 800×800 | 28-65 |

| 1010×1010 | 35-75 |

| 1200 ×1200 | 45-110 |

| 1400 ×1400 | 50-150 |

| 1600 ×1600 | 95-260 |

| 1800 ×1800 | 140-310 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat