Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Limestone, granite, cobble, calcite, pebble, cement clinker,dolomite, bluestone, construction waste, dry mortar and various stones, etc.

Cone crusher is mainly used for the secondary and tertiary crushing in mining and construction aggregates production industry. Cone crusher is applied to crush materials which are below 350 MPa, such as calcite, limestone, pebble, clinker, etc. in artificial sand making industry, concrete sand making industry, building materials and so on. Cone crushing machine has been extensively used for many years for its enormous crushing ratio, high efficiency, low energy consumption, and uniform product size.

FTM Engineers at Customer Site

According to the working mode of the production line, we have two types of cone crushers for your choice, mobile cone crusher and fixed cone crusher. Based on the requirement of material discharging size, cone crusher is laid for coarse crushing, medium crushing, and fine crushing. The standard crushing cavity is for coarse crushing; the middle-sized crushing cavity is for intermediate crushing; the short-sized crushing cavity is for fine crushing. Fote Machinery has different types of cone crusher for sale, like single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, compound cone crusher/Symons cone crusher, spring cone crusher, etc.

Cone Crusher in Stone Crushing Plant

Cone crusher is extensively applied in the mining industry, metallurgy, building materials, road construction, silicate making industry, etc. With high crushing ratio and even product size, it is suitable for medium and fine crushing of rocks below 350 MPa, such as iron ore, non-ferrous metal ore, granite, limestone, basalt, sandstone, pebbles, limestone, quartz, gravel and other more than 200 kinds of materials which are not of viscosity.

Comparison of Materials Before Crushing and After Crushing

Cone crusher parts mainly include a frame, a horizontal axis, a balanced wheel, an eccentric sleeve, an upper crushing wall (fixed cone), a low crushing wall (movable cone), hydraulic coupler, lubrication system, hydraulic system, and control system.

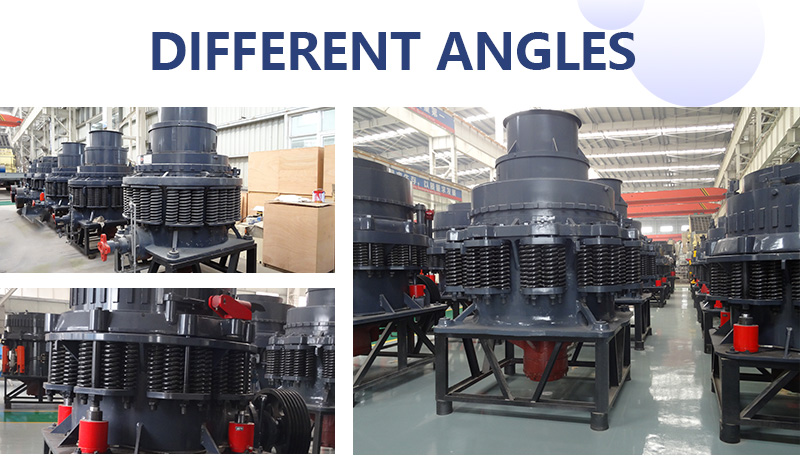

Different Angles of Cone Crusher

The entire crushing is completed by a fixed cone and the cyclic-moved cone. When a cone crusher works, the horizontal axis is driven by a motor with a triangle-belt and a wheel. Two different sized wheels make the eccentric bushing rotate through the axis. With the effect of the eccentric bushing, the cone axis moves in a cranking motion, which results in a regular near-and-far between the fixed cone and the crushing wall. Here, materials get constantly pressed and impacted until reaching the required size. Qualified products fall down and are blenched out through the outset.

Cone Crusher Working Principle

>>Similarity Between Cone Crusher and Impact Crusher

Cone Crusher and Impact Crusher can both be equipped with Jaw Crusher and used for secondary crushing and tertiary crushing in a stone production plant.

>>Difference Between Cone Crusher and Impact Crusher

With the impact crusher, materials are crushed by impaction. Here, materials are impacted between hammers and impacting plates repeatedly. While with cone crusher, materials get crushed by lamination. Rolling mortar wall moves towards the crushing wall and squeezes materials between them the qualified size.

Impact crusher has a smaller production capacity than a cone crusher. But with a good shaping capacity, it is usually used in middle and small-sized building material or conduction plants. Cone crusher that has a larger production capacity is more widely used in large ore dressing plants.

To crush materials within intermediate hardness, like limestone, impact crusher is the better choice. If a crushing process for materials with higher hardness is required, like for river pebble, granite, you’d like to choose a cone crusher.

Cone Crusher VS Impact Crusher

In Democratic Republic of the Congo, FTM cone crusher is used in the Quartz Sand Making Line with a capacity of 10T/H, input size of 150mm and output size of 4mm

FTM Cone Crusher in Congo

Fote Machinery is experienced in the production of crushing equipment. We have cone crusher for sale, which has complete models, reliable performance and high efficiency. Due to the reasonable cone crusher price and thoughtful after-sales service, we have been entirely approved by customers internationally.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

| Specification | Model | Diameter of large end of crushing cone (mm) |

Processing capacity (t/h) |

| Φ600 | PYB600 | 600 | 40 |

| PYD600 | 12-23 | ||

| Φ900 | PYB900 | 900 | 50-90 |

| PYZ900 | 20-65 | ||

| PYD900 | 15-50 | ||

| Φ1200 | PYB1200 | 1200 | 110-168 |

| PYZ1200 | 42-135 | ||

| PYD1200 | 18-105 | ||

| Φ1750 | PYB1750 | 1750 | 180-360 |

| PYZ1750 | 80-210 | ||

| PYD1750 | 60-180 | ||

| Φ2200 | PYB2200 | 2200 | 420-700 |

| PYZ2200 | 130-410 | ||

| PYD2200 | 80-200 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat