Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Cement, silicate products glass, iron ore, gold ore and other materials in silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal processing industry.

Also called cement ball mill, cement mill is the key equipment that grinds the crushed materials. The cement ball mill produced by Fote adopts high chromium alloy steel or double medium quenched steel liner, which has the characteristics of high quenching hardness and high toughness. The wear in production is small. The milling form of open flow provides a strong guarantee for the production of high-quality materials. According to different needs, FTM cement mill adopts two transmission forms including brim type and central shaft type, which is of flexible configuration.

Cement Mill at Fote Workshop

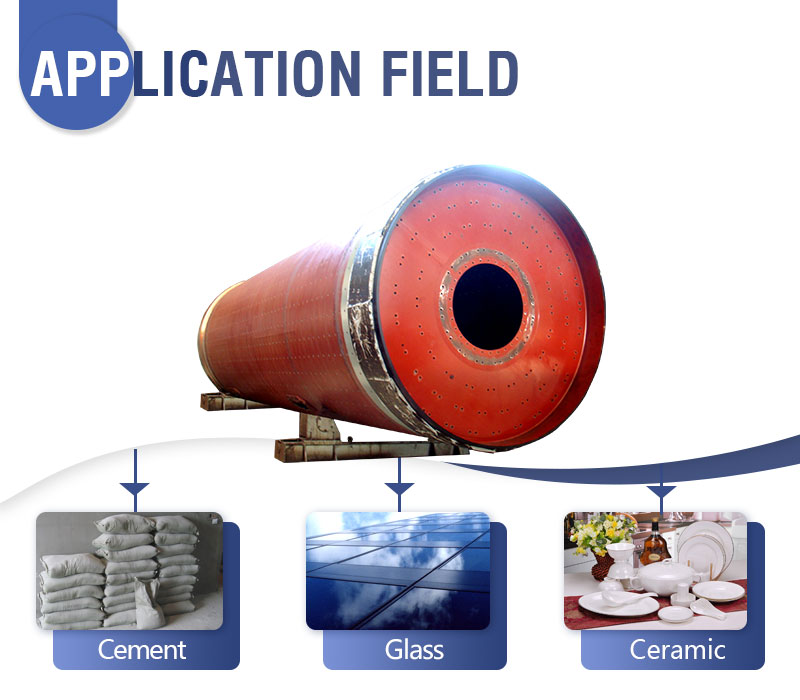

Cement mill kiln is mainly used for calcining cement clinker, which is divided into two categories: dry cement mill kiln and wet cement mill kiln. Besides, it can be used for glass, iron ore, gold ore and other materials in silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal processing industry and glass ceramics industry.

Application of Cement Mill

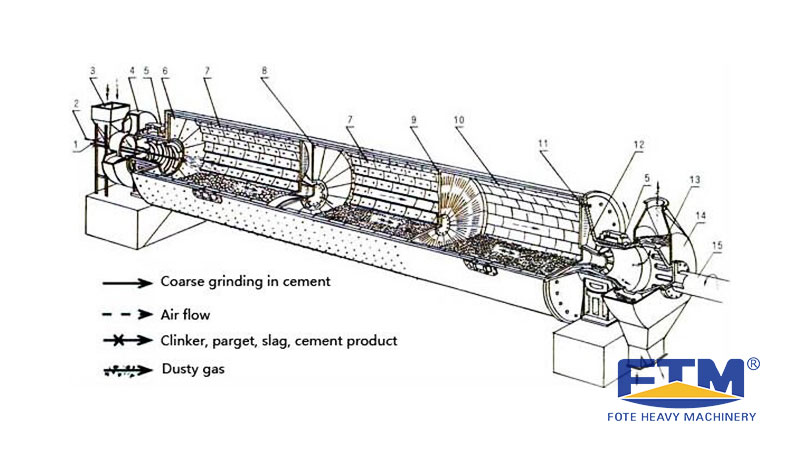

First of all, the material is fed into the first silo of the mill evenly through the feeding hollow shaft spiral. There are ladder liner or corrugated liner in the bin, and steel balls of different specifications are inside. The rotating of the cylinder produces centrifugal force to bring the steel ball to a certain height and falls down, which has a heavy impact and grinding effect on the material. After the rough grinding in the first silo, material enters the second silo through a single layer partition board. In the second silo, there is inlaid with a flat liner and a steel ball. Here the material is further ground. The powder is discharged through the discharge grate plate to complete the grinding operation.

Working Principle of Cement Mill

>>How to Judge the Feeding is Insufficient?

Adjustment: slowly increase the feeding capacity of the mill; if it doesn't work after a period of operation, increase the output of roller press; stabilize the new feed quantity after each parameter is displayed normally.

>>How to Judge the Blockage of the First Silo?

Adjustment: reduce or stop the feeding system; increase the mill ventilation volume; when the two methods fail, stop grinding and have a check.

In Zambia, FTM cement grinding mill is used for clinker with a capacity of 50TPH.

Fote Cement Mill at Customer Site

As one of China professional cement ball mill manufacturers, Fote machinery have senior engineers to provide the production process and design of a whole set of cement production line according to the requirements of customers. Besides, our engineers are willing to help you with the solution of mill machine selection and offering you the cement mill price and flow chart.

| Product specification (m) |

Milling form | Transmission form | Gear box | Motor power (kw) |

Production capacity (t/h) |

Total weight (t) |

|

| Model | Speed reduction ratio | ||||||

| Φ1.83×7 | Open flow | Brim | ZD60 | 4.5 | 245 | 6.5-8 | 43.8 |

| Φ2.2×7.5 | Open flow | Brim | ZD70 | 5 | 380 | 8-10 | 64.8 |

| Φ2.2×11 | Open flow | Brim | D110 | 35.5 | 630 | 12-13 | 104.6 |

| Φ2.2×13 | Open flow | Brim | D110 | 35.5 | 630 | 16-18 | 114 |

| Φ2.4×13 | Open flow | Brim | D110 | 35.5 | 800 | 20-23 | 130.6 |

| Φ2.6×13 | Open flow | Brim | MFY100 | 19.5 | 1000 | 28-32 | 158 |

| Φ3×9 | Circle flow | Brim | D125 | 41.2 | 1000 | 28-36.5 | 167 |

| Φ3×11 | Circle flow | Brim | D140 | 42.8 | 1250 | 36-47 | 180 |

| Φ3.2×13 | Open flow | Brim | D140 | 36.5 | 1600 | 45-50 | 225 |

| Φ3.5×13 | Circle flow | Brim | JDX1000 | 5.84 | 2000 | 60-65 | 275 |

| Φ3.8×13 | Open flow | Central shaft | MFY250 | 16.5 | 2500 | 60-62 | 320 |

| Φ4.2×13 | Open flow | Central shaft | JQS3550 | 15.6 | 3530 | 85-87 | 380 |

| Φ4.6×14 | Circle flow | Central shaft | JSI160-C | 14.6 | 4200 | 120-135 | 485 |

| Product specification (m) |

Milling form | Production capacity (t/h) |

| Φ1.83×7 | Open flow | 6.5-8 |

| Φ2.2×7.5 | Open flow | 8-10 |

| Φ2.2×11 | Open flow | 12-13 |

| Φ2.2×13 | Open flow | 16-18 |

| Φ2.4×13 | Open flow | 20-23 |

| Φ2.6×13 | Open flow | 28-32 |

| Φ3×9 | Circle flow | 28-36.5 |

| Φ3×11 | Circle flow | 36-47 |

| Φ3.2×13 | Open flow | 45-50 |

| Φ3.5×13 | Circle flow | 60-65 |

| Φ3.8×13 | Open flow | 60-62 |

| Φ4.2×13 | Open flow | 85-87 |

| Φ4.6×14 | Circle flow | 120-135 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat