By Hubery Editer

By Hubery Editer

Last week, a Pakistan customer contacted Fote engineer saying that, recently, the current of the main engine rises, while the current of the fan drops and hoping that Fote could offer one solution on it.

This customer introduced a 6R4525 from Fote two years ago. This Raymond mill has worked well since then. After communication, our engineer got to know that more limestone powder is needed these days. Our customer decided to increase the feed to the Raymond mill, which causes an overload and block to the wind pipe. The poor exhaust of the pipeline causes the circulating air temperature raise, so does the main engine. And the current of the main engine rises, while the fan current decreases.

Solution from Fote engineer:

1) Decrease the feed within the feeding overload of Raymond mill and clean the blocked pipeline;

2) Open the large air duct valve, the temperature of the incoming material is controlled below 6 °C.

Fote Raymond Mill Customer Site

Fote engineers often encounter Raymond miller customers who consult them about problems such as less powder discharged and the main grinding body vibration during working. According to past experience, most of these problems are caused by improper operation of technicians. If a Raymond grinding machine has been working for you for many years, its performance will be surly affected.

To know how to maintain Raymond miller, one should firstly know what is Raymond miller.

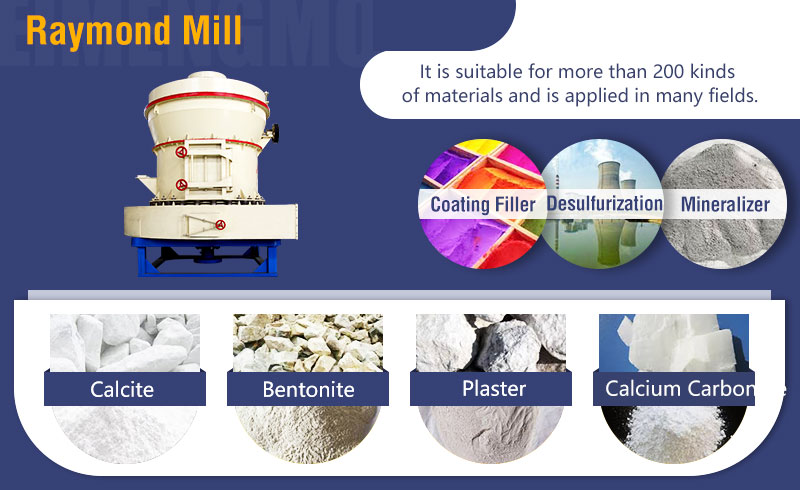

R-type Raymond mill is a classic and widely-used grinding machine. This type of Raymond roller mill is commonly applicable to over 280 kinds of non-combustible and non-explosive materials with Mohs hardness of not more than 9.3 and a humidity of less than 6%, such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, limestone, activated clay, activated carbon and bentonite, kaolin, cement, phosphate ore, gypsum, heat-insulating material, etc.

These materials can be used as fine powder production additive in mineral chemical industry, construction and other industrial fields. The finished product by the R-type Raymond miller machine can be controlled from 80-400 meshes.

Raymond Miller Application

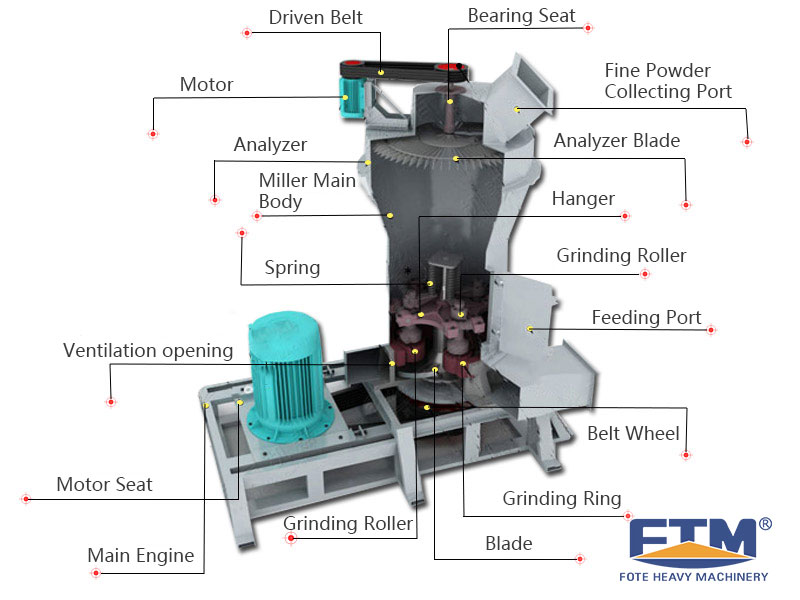

Raymond mill is mainly composed of main body, blower, analyzer, powder collector, dust collector, pipeline device and motor. The main body refers to the frame, blade, grinding roller, grinding rings, and housing, etc.

Raymond Roller Mill Structure

Large block materials are crushed by jaw crusher into smaller particles within the feeding size of Raymond miller. Then the materials are sent into the storage hopper by bucket elevator machine and fed into the main grinding chamber evenly and continuously by vibrating feeder.

Finished product is taken away by the air flow of the fan. Analyzer machine will classify the powder based on set requirements. Qualified fine powder enters the large cyclone collector for separation. Lastly, the collected qualified powder is discharged through the pipe.

The routine repair and maintenance of Raymond mill shall be mainly focused on the wearing parts and the bearing parts. How should the customer extend the life of the Raymond mill through routine maintenance and improve the working efficiency? Here are some suggestions from Fote engineer.

Raymond Grinding Machine Working Principle

Customers shall make detailed Raymond grinding equipment operation plan in advance, including production, progress, professional maintenance department and so on. Reasonable working arrangements and preventive measures can prolong the service life of Raymond mill and improve production efficiency.

√ “Safety Operating System for Equipment Maintenance” is a guarantee of a long and safe operation of Raymond grinding mill. Meanwhile, there should be necessary maintenance tools, lubricating oil and related accessories.

√ The operation and maintenance of the distribution control cabinet shall be the responsibility of the professional operator. Besides, the personnel training shall be carried out regularly.

√ Repair and replacement of easily damaged parts such as grinding roller, grinding ring, shovel knife, etc. should be examined and repaired regularly. Before and after operating the Raymond mill, pay a careful check to the connecting bolt and nut of grinding roller device to see if there is loosening phenomenon and whether the lubricating oil is fully added.

√ The roller bearing is refueled once in each shift. The center bearing of main engine is refueled every 4 shifts, and the blower bearing once a month.

√ The maximum temperature rise of bearing chamber should not exceed 70 ℃. When it is found that the bearing is overheated, the bearing and bearing chamber should be cleaned.

Fote Raymond Miller Machine

The main problems encountered in the use of Raymond mill are excessive noise, equipment vibration, no powder discharged or products decrease, not qualified powder, and so on. Most skilled operators can detect potential failures in advance through sound and finished product status in order to prevent and control the issues as soon as possible. Here are the skills for your reference given by the Fote engineers based on years of experience.

Ⅰ. No powder discharged or less powder discharged.

Reasons: 1) the powder locking device is not sealed well, resulting in powder suction;

2) the blades are worn too badly to scoop up the materials.

Solutions: 1) examine and adjust the powder locker and seal it well;

2) replace the worn shades with new ones.

Ⅱ. Larger or smaller finished powder than requirement.

Reasons: 1) the analyzer blade is so worn-out that it cannot work its own role of separation;

2) the air flow of the fan is not suitable.

Solutions: 1) replace the blade and narrow the air flow to solve the larger finished particles;

2) increase the air flow of the fan to deal with the smaller finished product particles.

Ⅲ. The current of the main engine rises while the current of the fan decreases.

Reasons: There is too much feed that exceeds the Raymond mill overload, resulting a block in the air exhaust pipeline. Circulating air flow heating rises the machine temperature. Thus, the main engine current is increased and the fan current is decreased.

Solutions: 1) decrease the feed within the feeding overload of Raymond mill and clean the powder blocked pipeline;

2) open wider the air duct valve and control the temperature of the fed material below 6 °C.

Ⅳ. Large main engine noise and large main engine vibration.

Reasons: 1) the feed volume is small;

2) the blade wear is serious and the material cannot be shoveled;

3) the material is hard with large impact, or there is no material layer;

4) the roller grinding ring is out of circle;

5) the anchor bolt is loose.

Solutions: 1) adjust the feed quantity;

2) replace the worn-out blade with new one;

3) control the feed particle size;

4) replace the grinding roller and ring;

5) tighten the anchor bolts.

Ⅴ. Fan vibration.

Reasons: 1) there is an accumulation of powder on or wear imbalance of wind blade;

2) anchor bolts are loose.

Solutions: 1) clean the accumulated powder on the wind blade or replace the worn blade;

2) tighten the anchor bolts.

Ⅵ. Overheated transmission device and the analysis machine fuel tank.

Reasons: The oil is of large viscosity and thickness. The screw pump cannot oil the upper bearing causing an oil shortage.

Solutions: 1) check that if the grade and viscosity of the oil are in accordance with the requirements;

2) check the operation direction of the analyzer machine.

Ⅶ. Damaged powder bearing of grinding roller device.

Reasons: 1) oil is cut off, or sealing ring damaged;

2) lack of maintenance and cleaning for a long time.

Solutions: 1) refuel the grinding roller device according to the specified time;

2) regular cleaning and replacement of oil sealing device are needed.

Fote Raymond Roller Mill

Ⅷ. Fault description: after shutdown, open the grinding cavity and push the wheel with your hand to find that some rotors do not turn, and the sticks and rings are broken down.

Reasons: it is caused by poor lubrication on roller bearing.

Ⅸ. Fault description: after being torn apart, the sliding bearing of the suspension shaft is found locked tightly, and there is a large amount of oil mud in the suspension cavity.

Reasons: the outlet is too large, the air pressure of the suspension shaft inner cavity is less than that of the grinding cavity, which causes the dust enter the suspension cavity.

Ⅹ. Fault description: severe vibration and noise

Reasons:

1, The feed quantity is small.

Raymond grinding mill is to grind the material through the grinding of the rollers and rings. If the feed quantity is too small, there cannot form a material cushion between the high-speed rotating roller and the ring. The collision of iron to iron will inevitably lead to the violent vibration and noise of the Raymond grinding mill main engine.

2, The material is too hard.

There is a required hardness of the material that can be normally ground by the mill. Too hard material will cause great impact.

Shipment of Fote Raymond Miller

Fote has a 40-year experience in the production of Raymond mill, which is sold with a variety of models. We have more than 360 professional engineers to provide you with custom services. Welcome to chat online with our sales or leave a message to get the latest quote and the current month discount.

Online Chat

Online Chat