By Dora Editer

By Dora Editer

The global annual production of aggregates in 2018 has reached 40 billion tons. It is estimated that this number will be 51.7 billion in 2019. With the increasing development of infrastructure, there is a gradually growing demand for construction aggregates.

There are types of aggregates, like mineral aggregates, glass aggregates, slag aggregates, natural aggregates, recycled aggregates, etc. Types of aggregates used in different fields such as in base and asphalt for pavement, road, etc., in concrete mixing with cement, in glass or ceramics manufacturing, in mortar for buildings, and so on.

Lots of materials can be used as the source of construction aggregates. For example, we have building waste, waste concrete, rock and stone like gravel or pebble, limestone, basalt, andesite, granite, etc.

While here in this paper, we are going to talk about something about construction aggregates.

What is worth being mentioned is that different buildings have different requirements for aggregates. This paper only provides you with some standards to judge the quality of the aggregate and what kind of equipment is suitable for aggregate production.

The detailed operation and solution are depended on the tests by skilled engineers.

Construction aggregates, or simply aggregates, is the key material for concrete, which not only plays the part of the backbone and filling-up but also reduces the shrinking of concrete to hold the increasing crack. This is to lower the concrete hydrothermal process and improve the durability of the building.

Suitable gradation reduces the mortar quantity as well as the unit volume water consumption and gel material consumption accordingly. The mixture is not easy to be split.

In the order of aggregates size, the following content will introduce different sizes of aggregates from stone to sand as well as other specifications.

Stone can be seen everywhere. While how much do you know about the stone aggregate in construction?

In the mining industry, the particle of stones is usually larger than 5mm, which always lies between 9.5mm and 37.5mm (3/8 inch-3/2 inches). This kind of stone is also called coarse aggregates.

Crushed stone and pebbles are two common coarse aggregates. Crushed stone is made from any stone or rocks by crusher and then by the screener. Pebbles are got by natural weathering, water transport, sorting and accumulation.

Commonly used of different sizes of stone aggregates

No matter the coarse aggregates are got naturally or artificially, it can be used as stone aggregates.

The size of the stone usually used in the building is 20mm, and sometimes stones of larger size like 40mm are more used in large-volume concrete.

Other commonly seen coarse construction aggregates specification:

| Global Standard | |

| 5-10mm | - |

| 10-20mm | - |

| 16-31.5mm | - |

| 10-15mm | 1/4-1/2 inch |

| 15-20mm | 1/2-3/4 inch |

The stone aggregates discussion is finished. Next is the sand, which is derived from stone and rocks.

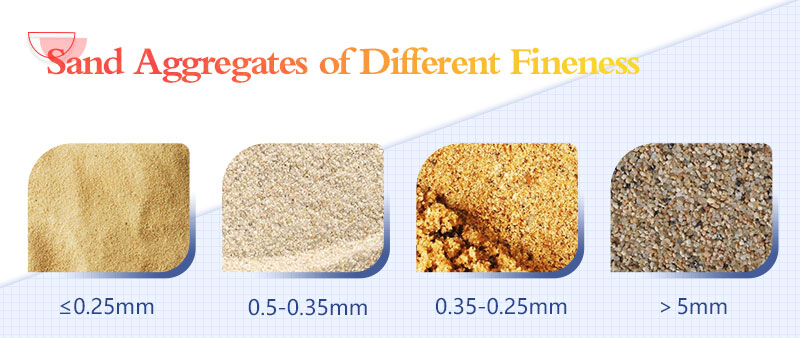

Sand refers to construction aggregates below 5mm or 0.2 inches. Sand can be small spalls formed and accumulated naturally by mountains, rivers, lakes, and seas, which is also called natural sand construction aggregates.

Besides, sand can be produced by mining machines from large stone or rock, which is called mechanism sand or artificial sand.

Sand is classified into 3 grades based on the fineness modulus,

Fine sand: 2.2-26

Medium sand: 2.6-2.9

Coarse sand: 2.9-3.2

Correlation table of fine aggregates fineness modulus:

| Fineness modulus | 1 | 2 | 3 | 4 | 5 | 6 |

| Size (mm) | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 |

Note: Fineness modulus is used to show the average size of every particle of the tested sand. It is calculated by standard screens with screening and analyzing.

Usually, crushed products over 3.2 fineness modulus are not used as the raw material of high-grade concrete. Skilled engineers get the ideal gradation of aggregates by combining two kinds of crushed products with fine modulus.

Sand aggregates of different fineness

Sometimes, people in some places express construction aggregates specification with such expression like 5-1, 2-4, 4-6. This is for the disunity sizes of the aggregates. When the vibrating screen is used to finish the classification, an expression presenting the particle size of the majority aggregates is needed. That expression refers to the range.

The unit is centimeter. For example, in the expression of 1-2, the “1” refers 1 centimeter and “2” refers to 2 centimeters, that is, most particles in this batch of construction aggregates are from 1cm to 2cm.

Here are some references,

| Expressions | Size | Construction aggregates |

| 0-5 | 0-5mm | Sand |

| 5-1 | 5-10mm | Stone |

| 1-2 | 10-20mm | Stone |

| 1-3 | 16-31.5mm | Stone |

| 2-4 | 10-15mm | Stone |

| 4-6 | 15-20mm | Stone |

Size is certainly not the only judgment of construction aggregates. Engineers will take the size, purity, etc. into consideration when complete the gradation of the aggregate.

Shape

The ideal shape of construction aggregates is cubic. While it is admitted that there appear needle or schistose particles. When the content of needle or schistose construction aggregates is too high, the modulus of rupture and the cohesion strength is decreased.

Content of Clay and Dust

Too much clay or too much dust makes it easy for concrete to be out of shape and lower the strength of the materials. Buildings constructed by such concrete will be easily be cracked, which is very dangerous.

So to say, construction aggregates to buildings is like a bone to humans. When producing construction aggregates, we shall pay attention to both the raw materials selection and the proper process of the materials.

Based on experience, crushing machines and sand making machines are equipment used to shape the construction aggregates. And the wheel sand washer and spiral sand washer are used to lower the content of clay and dust.

In the following introduction, we are going to show you how to improve the quality of the construction aggregates in the order of aggregate production and the above-mentioned aggregate standard.

This is to help the investors to produce satisfactory construction aggregates.

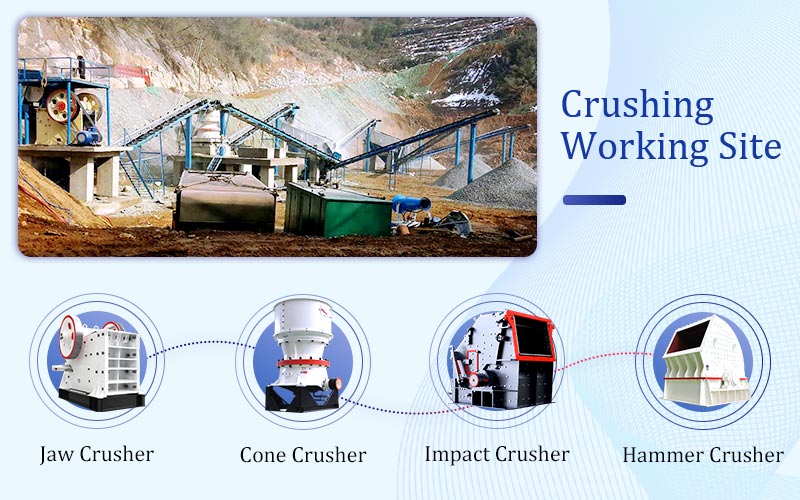

Aggregates production site

As it is known to all, the first step of aggregates production from a big rock. In this process, crushers and screeners are used.

If you need the stone aggregate above 5mm, the crushing plant with a crusher as the main helper meets the requirements.

There are mainly two series of crushing equipment used in this process, pressure crusher and impact crusher.

◆ If you need to process high-hardness materials, you'd better choose pressure crusher to lower the harm to wearable parts, such as jaw crusher, cone crusher, roller crusher, etc.

◆ On the contrary, impact crushing equipment is the better choice. Impact crusher, hammer crusher or hammer mill, compound crusher, single-stage crusher are selectable.

Some construction fields have higher requirements on the aggregate shape. For this situation, impacting crushing equipment shall be selected. While on other conditions, these two types of crushers are both available.

Coarse aggregates equipment--crusher

Rome was not built in a day. And a stone turning into sand is not by a snap. What is mainly used in sand production is the sand making machine.

Sand maker machine is sometimes called sand making machine. Due to its working principle, sand making machine is one kind of impact crushing equipment. Therefore, the sand making machine has the function of product shaping on construction aggregates with a smaller discharge size.

The two most common and popular fine aggregate making machines for shaping are of HVI type and VSI type, of which the former is the latest generation.

The two machines use the combination of stone to stone and stone to iron with a design of the deep cavity rotor design. This design not only improves the production capacity of machines but also modifies the shape of discharged construction aggregates with a better impact angle to meet the construction requirements.

Both the HVI sand making machine and the VSI sand making machine can complete sand production and shape simultaneously. The overall processing effect is better than the traditional sand machine. If a larger capacity is needed, the HVI sand making machine can win with more advanced technology.

Normally, the crusher will be equipped on the fine line to break the bulk material to an appropriate size in the primary stage. This is to improve the sand-making efficiency and reduce the pressure of sand making machine.

Fine Aggregates equipment--Sand Maker

As mentioned above, the clay and dust content in sand aggregate affects the quality of the concrete. Poor concrete results in the building being not strong enough. Therefore, a machine that can improve the purity of fine construction aggregates is very important.

The equipment to meet purity requirement can be a wheel sand washer or a spiral sand washer.

Wheel sand washing machine like a small ferris wheel in a bucket. It has an adjustable overflow weir plate and good tightness. While different from the wheel sand washing machine, the spiral type uses the spiral device to stir the sand and stone for cleaning. It can not only improve the purity but also grade the material with different fineness.

Both kinds of washing equipment are suitable for all kinds of crushed fine aggregate (also named artificial sand) and natural sand. The sand after cleaning is of high quality and can be applied to more fields, bringing more profits to investors.

Wheel&Spiral sand washing machine

Everything is ready. We have got aggregates with perfect shape and moderate purity. The last is to get construction concrete by sound gradation.

Usually, this is finished through a screening test by engineers.

According to experience, the optimal aggregate gradation has the following characteristics:

1) Reducing the poriness in the concrete to the minimum. This is to reduce the amount of cement and ensure the concrete density;

2) Reducing the total surface area. This is to reduce the water demand to wet the surface of the aggregates and to lower the amount of cementitious material;

3) Containing a small number of fine particles. Because the proper content of fine particles helps the concrete to meet the requirements of workability.

Concrete with qualified aggregates gradation

The ideal aggregate gradation depends on the screening method. The sieving experiment process of coarse construction aggregate and fine construction aggregate is the same. The grading proportion can be determined in advance by experiments with test sieves of different apertures.

60%-70% of the contents of concrete are aggregate. Whether it is fine aggregates or coarse stone aggregates, proper aggregate gradation has a direct and good influence on the concrete workability, strength, impermeability, frost resistance, corrosion resistance, and durability.

Besides, suitable aggregate gradation assures the concrete high grade, which is more beneficial to both the manufacturers and the buyers.

In conclusion, both in terms of revenue and practicality, fine grain shape, ideal gradation and appropriate purity of construction aggregates can not only generate more income but also bring credibility to producers. And the resulting buildings will be safer and more durable.

As a manufacturer of aggregate equipment, Fote is willing to provide investors with high-quality construction aggregates production solutions with our professionalism. Welcome to make free online consultation with experienced engineers.

Online Chat

Online Chat