By Hubery Editer

By Hubery Editer

As a kind of highly controversial non-metallic mineral, talc has been in the list of the most searched hashtags these years. While it cannot be denied that as a soft mineral with high glossiness, good transparency and strong soapiness, talc ore is not only applied in cosmetics, food, medicals but also painting, ceramics, plastics, chemicals and other industrial areas.

Now let's remove the negative tags of talc and check how to make talc powder, which is one of the worldwide most used powder.

How to make talcum powder from talc ore?

Since we will offer a detailed introduction on talcum powder production, here concludes a general process for time-saving.

The equipment needed for talc powder production varies on industrial requirements. The process of talc powder production is rather easy. Only three steps are needed, crushing, grinding, and purification, you will get the talc powder you need.

machines mainly used in talcum powder production

The main links are extracted based on two technology for your reference.

A, Grinding with High-Pressure technology

In this process, talc ore is sent by vibrating feeder into the crusher. After crusher, the talc ore is entered into the dryer machine for dewatering. Next, the dry talc is crushed again into smaller particles and then ground by the Raymond mill. If needed, the talc powder can be sent into the high-pressure grinding mill to be ground into a finer powder.

High-pressure grinding process

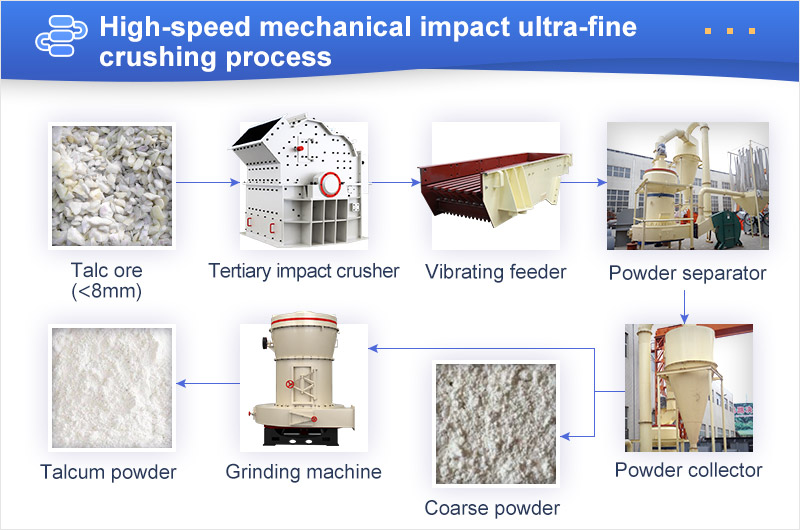

B, Hi-speed impaction crushing

Talc ore is crushed into 8mm and then fed into the tertiary impact crusher. Then high-efficiency classifier separates the coarse powders in the crushed talc from the fine one. After the separation, coarse talc powder can be sent into the grinding machine for further process or packed as a product.

Hi-speed impaction crushing process

These two processes can be followed by suitable purification to get the required talcum powder product.

Now, it's time to get details of the main process producing talcum powder.

This is based on the differences between talcum ore and gangue minerals in selective crushing and shapes. Impact crusher and vibrating screen are adopted to separate most associated quartz and carbonate minerals. During the selective crushing, the investors can choose jaw crusher, impact crusher or hammer crusher, etc.

Jaw crusher is a kind of "crush-it-all" crushing machine, which uses the extrusion from the movable jaw to the fixed jaw.

The impact crusher and hammer crusher are one type of crushing equipment. They both work on the principle of impaction. The hammers in the machine rotate at high speed, knocking the talc ore to the crushing wall. With several crushing, the talc ore is thus broken into the required size.

A good shape of the particle is not required in the production of talcum powder. And talc ore is very soft with a mosh hardness of 1, therefore, you can choose any one kind of machine based on budget and capacity required.

The screening equipment for talcum powder production can be a vibrating screen with continuous action. There are other connective equipment like conveying equipment, feeding equipment, etc. to be matched according to the production equipment.

Grinding is the key stage from talc ore to talcum powder. Speaking of grinding, people will think of the grinding machine.

At present market, on different working principles, the mostly used grinding machine is divided into two types, grinding mill and ball mill. In addition to the different working principles, in the talcum powder production, the capacity and the product's fineness are different.

Grinding mill like Raymond mill produces talcum powder with high fineness, up to 800-1000 mesh. And the three-ring medium-speed micro grinding mill even produces talcum powder with 3000 mesh. While, accordingly, the production capacity of a grinding mill is low, 0.6-320 tons per shift.

The 0.65-615TPH ball mill can meet the need for large capacity in producing talcum powder. The product particle is coarser. The common product fineness of the ball mill is 200 mesh. The good news is that the particle size can be adjusted by grinding media inside.

Grinding machine selection for talcum powder production

Anyway, in different manufacturing fields like coating, paper-making, plastics, rubber-making, etc., there are various requirements for the fineness of talcum powder. In this important stage, you shall choose a suitable machine according to the target customers.

Professional engineers suggest the experiences and user feedback that grinding machine such as Raymond mill be a better choice.

The fineness of the talcum powder after grinding machine meet the requirement, but there are other requirements, such as the whiteness of the talcum powder and the content of iron or other impurities. Considering this, magnetic separation, flotation, calcination or other methods for purification are needed.

Taking the magnetic separation as an example, let's find out how is the last step of talcum powder production.

Magnetic separation is based on the magnetic differences between talc and the associated minerals. With the function of the magnetic force and other forces, the separation and purification are finished.

Siderite, pyrite, tremolite and other magnetic impurities are removed by magnetic separator. According to the data, a suitable magnetic separation process and equipment can reduce the iron content of talc concentrate from 4%~5% to less than 1%.

Magnetic separator

To make powder from some low-grade talc ore, flotation is generally needed to improve the grade. The talc flotation process is relatively simple, using collecting agents, foaming agent and other specific agents. Most talc ores require only one coarse dressing, one sweep dressing and 2-4 times of selection to obtain the final talcum powder.

Talc ore is rich in color. In different industries, talcum powder is needed with different soapiness, whiteness, purity, flake and fineness.

According to the product requirements, the raw materials of talc ore can be hand-selected first to separate the lumpy associated minerals. This work shall be done by experienced workers through touch, observation and other methods.

This process is not necessary and only suitable for high-grade talc ore processing. Besides, there are higher requirements for the operators. It is gradually replaced by photoelectric color selection these years.

In fact, in the production of talcum powder, the manufacturing method is not only one or two. Professional engineers give corresponding recommendations according to the characteristics of the raw talc ore. Multiple methods are often the best choice.

If you want to purify, remove impurities and whiten talc ore and talcum powder, you need to be familiar with the mineral characteristics of regional talc ore. And the ability to choose professional and appropriate solutions and equipment is needed to realize the low-cost production of talcum powder.

Fote Machinery has professional engineers providing you with suitable crushing, grinding and purification equipment solutions according to the different raw talc. Besides, if you have any questions about the choice of talcum powder manufacturing equipment, please feel free to email quote@sinoftm.com or contact our staff online.

Online Chat

Online Chat