Email (quote@sinoftm.com), we will reply to you within 24 hours

Applied Materials: Pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, cement clinker and some metal.

Diabase is a widely distributed ore in nature, its main components are pyroxene, feldspar, biotite, quartz and so on, the color is usually dark gray, gray-black and so on. Diabase stone is widely used in chemical industry, building materials, water conservancy, power generation, environmental protection and other fields after crushing and processing.

Diabase stone is often a rock bed, a rock wall, a rock vein, also as a rock neck or a rock strain, filled in basalt crater. The above occurrence of diabase is the main sign that it is different from gabbro and basalt stone. Diabase is smaller in size and more suitable for fine aggregate production. But both can be processed into high-quality building materials.

The Difference Between Diabase and Basalt

Basalt and diabase's hardness are higher compared with other rock and high silicon content, which belong to materials that are hard to crush in actual crushing operations or have higher crushing costs. More generally, basalt and diabase are tough and hard materials. So, the crushing process of basalt or diabase should be reasonable, taking the investment cost of crushing project and production cost of diabase or basalt mining crushing plant into account at the same time.

The equipment of diabase or basalts in crushing processing is jaw crusher, impact crusher and cone crusher. Below we carry on the detailed analysis to these three kinds of crushing equipment.

The jaw crusher is mainly used for crushing medium strength materials, and it is an early stone crushing equipment. Its structure is simple and operation is reliable. The equipment is widely used in the application field of diabase and basalt crushing. It is specially developed by Fote Machinery for diabase and basalt materials. The production capacity of diabase and basalt is very high by using jaw crusher, which has won majority of the praise from customers.

The impact crusher is a new type of high efficiency crushing equipment, which was developed by Fote Company is based on the absorption of fine technology at home and abroad and combining with the actual production conditions of diabase and basalt crushing equipment. The equipment has strong pertinence and outstanding crushing ability, so it is a high-quality choice for the crushing of diabase and basalt materials.

Cone crusher is famous all over the world for its high speed, high crushing and unique structural design. It is a new generation of broken diabase and basalt materials.

In diabase or basalt mining crushing plant,the loss of jaw plate, plate hammer, impact plate and other wear-resist parts is very high; the production cost of customers is much higher than that of basalt stone. So, in the design of crushing process, we should choose the crushing equipment with laminated crushing principle, for example, diabase/basalt stone crusher, so as to reduce the loss of wear-resist parts.

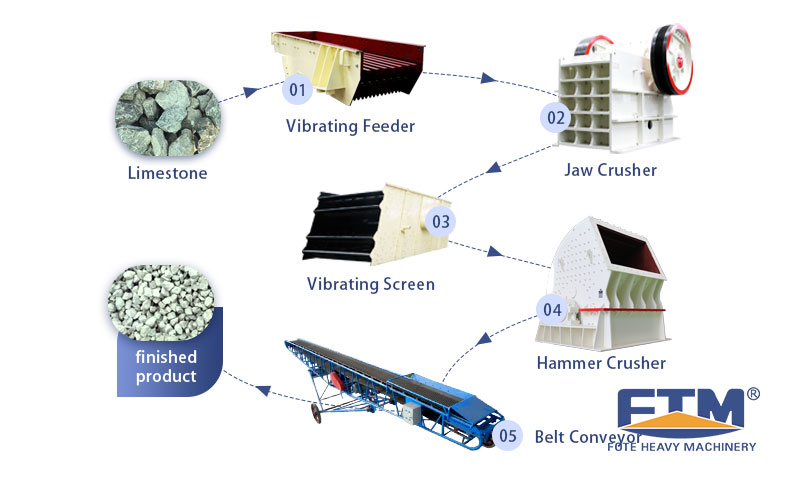

The Production Line of Diabase or Basalt Crusher Machine

The typical lamination crushing equipment is two-stage jaw crusher or jaw crusher plus cone crusher. If the customer has higher requirements for the final particle size, we can also configure impact crusher for stone shaping, thus forming a three-stage crushing process. Although tertiary crushing will inevitably increase investment costs, the production cost of tertiary crushing is considerably reduced for long-running quarries. The following is the basic configuration of basalt crusher. Each configuration has its own function; the specific design is based on the actual situation of the customer.

If the market have certain requirements on the grain shape of finished stone, and the customers also want to lower the cost of wearing parts per ton, coarse jaw crusher+fine crusher/spring cone crusher as primary crusher and secondary crusher would be a good choice. Impact crusher can be put on the position of three-stage crushing, thus reshaping the stone to be crushed. In this way, you can not only reduce the wearing cost of impact crusher, but also get the stones with good grain shape.

Consultation of Basalt Mining Crushing Plant Price: Send email to quote@sinoftm.com, leave a message on our website or contact our online customer service.

|

Model

|

Feed opening

(mm) |

Max.feeding

size (mm) |

Adjusting range

of discharge opening (mm) |

Processing capacity

(t/h) |

Rotation speed of

eccentric shaft (r/min) |

Motor power

(kw) |

Total weight

(t) |

Dimensions

(L×W×H) (mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-21 | 300 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 275 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 250 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 250 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 15.6 | 2720×1950×1600 |

|

Model

|

Max.feeding

size (mm) |

Adjusting range

of discharge opening (mm) |

Processing capacity

(t/h) |

| PE-150×250 | 125 | 10-40 | 1-3 |

| PE-200×300 | 180 | 15-50 | 2-6 |

| PE-200×350 | 180 | 18-70 | 3-10 |

| PE-250×400 | 210 | 20-60 | 5-21 |

| PE-400×600 | 340 | 40-100 | 16-64 |

| PE-500×750 | 425 | 50-100 | 40-110 |

| PE-600×750 | 500 | 150-200 | 80-240 |

| PE-600×900 | 500 | 65-160 | 50-160 |

| PE-750×1060 | 630 | 80-140 | 110-320 |

| PE-800×1060 | 640 | 130-190 | 130-330 |

| PE-830×1060 | 650 | 160-220 | 150-336 |

| PE-870×1060 | 660 | 200-260 | 190-336 |

| PE-900×1060 | 685 | 230-290 | 230-390 |

| PE-900×1200 | 750 | 95-165 | 220-380 |

| PE-1000×1200 | 850 | 195-265 | 315-500 |

| PE-1200×1500 | 1020 | 150-350 | 400-800 |

| PE-1500×1800 | 1200 | 220-350 | 500-1000 |

| PEX-150×750 | 120 | 18-48 | 8-25 |

| PEX-250×750 | 210 | 25-60 | 13-35 |

| PEX-250×1000 | 210 | 25-60 | 16-52 |

| PEX-250×1200 | 210 | 25-60 | 20-61 |

| PEX-300×1300 | 250 | 20-90 | 16-105 |

Professionalism builds quality and integrity creates international Fote Brand. Henan Fote Heavy Machinery Co,. Ltd, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing.

Understand customer needs and provide quality technical consulting services

Provide on-site installation service, professional technical team on-site installation

Provide regular return visit service to help users optimize equipment maintenance

Online Chat

Online Chat